Transmission mounts ensure smooth shifts when accelerating and decelerating by absorbing vibration and providing a stable base for the engine and transmission. By design, transmission mounts are quite durable. However, when one goes bad, the powertrain unit will start to move forward and backward each time the transmission shifts a gear. You might hear knocking coming from the engine bay when accelerating or decelerating, and other components might be damaged. Fortunately, replacing transmission mounts is usually quite easy, even for weekend mechanics. If you are suspecting one of the transmission mounts on your car might be faulty, and you don't really know where to start, this article is for you. We will cover everything you need to know to quickly identify defective transmission mounts, the most common signs and symptoms of faulty ones as well as how to easily replace them with only essential tools.

Let's go!

What is a Transmission Mount?

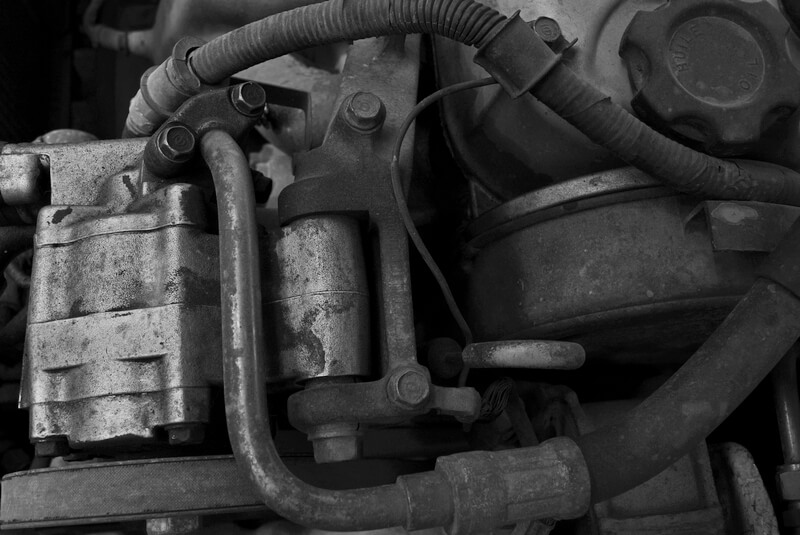

To build cars that are free of vibration, manufacturers install shock-absorbing mounts to the engine and transmission. The mounts attach the components to the frame or subframe of the vehicle. Most vehicles will have at least two engine mounts, but often only one transmission mount. There are many different types of mounts, but most of them consist of two metal components with a thick rubber or synthetic material like polyurethane in between. The outer metal housing is bolted onto the frame or subframe of the car while the inner sleeve is attache to the transmission. In sim

The lack of a rigid connection between the two metal components allows the transmission to move slightly but prevents it from twisting or jerking. The transmission mount absorbs vibration and torque to enable smooth shifts when accelerating and decelerating.

If the transmission or engine were directly bolted onto the frame of the car, even at idle, the vibration would make it impossible to stay in the car. Forget about listening to the radio of keeping a full coffee in the cup holder! Race cars sometimes use "solid mounts" or might chain the engine to the frame to prevent wasting any horsepower because of the engine moving slightly backward when accelerating. However, if you once had a ride in a race car before, you already know how they vibrate like hell. These cars aren't intended to be comfortable at all, so it's not a problem.

Signs of a Bad Transmission Mount

The most common symptom of a bad transmission mount is harsh shifts, particularly when engaging in Drive or first gear. The harshness is a result of the transmission moving more than it should. It's also likely that drivers will feel excessive vibration when a transmission mount is failing. In particularly bad situations, if the rubber part is completely damaged, the inner sleeve might sit directly onto the outer housing, which might cause the transmission to be misaligned with the driveshafts. When it happens, no matter if the car is equipped with a transverse or longitudinal engine, the transmission will be slightly crooked, which may cause the driveshaft(s) to rotate erratically, which will either damage the joints or create severe vibrations as the vehicle accelerates.

Both automatic and manual transmission vehicles use transmission mounts. Manual transmission cars can show evidence of a bad transmission mount when shifting into gear. Drivers may even experience problems with the clutch because of excessive transmission movement resulting from a bad mount.

Driving with a bad transmission mount can cause knocks, thumps, banging, and other impact noises caused by the inner sleeve coming into contact with the outer sleeve.

How Much Does Replacing a Transmission Mount Cost?

The cost to replace a worn-out transmission mount is usually less than you might think. A repair shop will charge somewhere between $250 and $400 to do the job, depending on its hourly rate. The repair cost is somewhat more than other components due to the difficulty of accessing the transmission mount. Depending on the location, it can take several hours for a mechanic to remove and replace a transmission mount.

In fact, replacing tranny mounts used to be a pretty straightforward job back in the 90s. However, as cars get more and more advanced, they tend to have an increasing number of components under the hood. Before, removing the air intake box and the battery was usually enough to reach the mount. Nowadays, it's not uncommon to have to remove advanced ABS modules, hybrid system components, and tons of plastic covers to even be able to get a glance at it.

For the same reason, transmission mounts on front-wheel-drive cars and minivans with transverse engines may be more of a challenge to replace. On a rear-wheel-drive vehicle, the transmission mounts are usually easily accessible. Still, you might need to live the car on a hoist since the transmission will probably need to be lifted with a transmission jack.

The cost of the part is usually very affordable. As a general rule, we could say that most transmission mounts cost between $25 and $150, but, as with most other car parts, it really depends on your car model. In most cases, though, expect the cost to be on the lower side. Even on luxury vehicles, transmission mounts are often still quite affordable. After all, it's just a piece of rubber between two pieces of metal. For example, a transmission mount on a 2006 Honda Civic costs $35 while the same part on a 2015 Audi RS5 4.2L V8 only costs $42.

[divider style="solid" top="20" bottom="20"]

See also: Is Driving with Broken Engine Mounts Safe?

[divider style="solid" top="20" bottom="20"]

How to Inspect a Transmission Mount

Inspecting the mount for damage is a simple procedure anyone can do at home. The hardest part, in fact, is to remove everything that is in front of it, so you have a look. Once it's done, it all comes down to a visual inspection.

Many older, high-mileage vehicles will have mounts that crack and collapse from driving. Cracks do not always mean the mount is worn-out, though, but might indicate that the rubber as dried out. A transmission mount that looks squeezed down or is pushed out of shape will need to be replaced.

Most transmission mounts attach to the cross-member, connecting the frame rails or subframe, while the transmission simply rests on top of it. However, engineers sometimes like to play games and will integrate the mount into the crossmember, making its replacement a lot more expensive.

With transmissions that attach on top or through the mount, you can place a floor jack under the transmission and use a piece of wood across the pan or another strong point to gently lift the transmission. If the rubber part separates from the metal pieces, it will need to be replaced.

You can also use a pry bar to move the transmission forward and backward to see if the inner sleeve is still attached to the rubber and if the rubber is still attached to the outer metal piece. If it's not, replace it as soon as possible.

How to Replace a Transmission Mount

Removing a Transmission Mount

First, you will need to raise the car or truck and safely support it on jack stands. Never work under a car held only by a floor jack. Place a floor jack under the transmission in such a way as to support and lift it. You can also buy a specialized cradle to convert a standard floor jack into a transmission jack. The cradle can be invaluable, mainly when working on large, bulky transmissions without good balance points. Otherwise, you may also use ratchet straps or some other reinforcement to ensure the transmission does not fall from the jack when you change the mount.

When the transmission is securely supported, loosen and remove the nuts and bolts holding the transmission to the transmission mount and the crossmember. Gently lift the transmission to remove the mount. It is essential to raise the transmission as little as possible and to pay attention to bind points that might crush hoses or pull out fuel or brake lines.

If you can't lift the transmission high enough to remove the mount, you will need to lower the cross-member, which usually connects to the subframe with two or four bolts. Do not remove the bolts entirely before supporting the crossmember and securing the transmission. Remove the mount from the crossmember.

Installing a New Mount

You may find the new mount to be slightly more challenging to install than the old mount was to remove. The new mount will be taller because the weight of the transmission has not broken it down yet. Make sure the bolt holes line up, and the mount is in the same direction as the old one. If the crossmember was lowered to replace the mount, install the mount to the crossmember before fitting it to the transmission. Do not tighten the bolts to the mount yet.

Once the mount is in place, torque the crossmember to the correct specification. If you are not sure what the specs are, make sure to look inside your car's repair manual first. Always secure the crossmember before lowering the transmission onto the mount. Torque the transmission mount bolts to the factory specification, reinstall all the components you had to remove, and that's it!

Regular Inspection

If you find your vehicle in need of a new transmission mount, you should also plan to inspect its engine mounts. Mounts tend to age at the same time, and the enormous amount of force the mounts absorb means they should all be in a similar condition to work best.

A good practice is to inspect u-joints and the remainder of the driveline while replacing mounts. It is common for a bad mount to create wear on other driveline components resulting from vibration when driving. Inspecting other parts can prevent costly breakdowns and eliminate annoying rattles and vibrations. Make sure to reinstall heat shields and splash pans after working on the transmission mount. Missing heat shields and splash pans can result in numerous problems, and may even present fire hazards.

Last Words

The cost to replace a transmission mount on your vehicle is usually affordable, and the job is an easy one to do at home. Furthermore, the cost of replacing a broken mount is often a lot cheaper than other repairs that might result. While mount failures are not that common, owners of older vehicles or cars with high mileage should inspect transmission and engine mounts regularly to ensure they are still in good condition. Even mounts that look to be in good condition can be defective. In all cases, if you find one that doesn't look that good, don't hesitate to replace it. Better safe than sorry!