Every car enthusiast knows a turbo can significantly improve an engine's performance. However, many petrolheads only have limited knowledge of how it actually does its thing. If it's your case, here's everything you need to know about how a turbocharger works and why you need one!

Who Invented the Turbocharger?

Alfred J. Büchi (1879–1959) was an automotive engineer who worked for the Gebrüder Sulzer Engine Company. His design sent power through a compressor utilizing an exhaust-driven turbine shaft. He patented his design in Germany in 1905, but he continued improving it until his death.

However, Sir Dugald Clerk (1854–1932), the Scottish inventor of the two-stroke engine, previously explored using two separate cylinders to separate the compression and expansion stages of internal combustion. It had slightly similar results to supercharging, increasing both airflow into the cylinder and the amount of fuel that could be burned. Other engineers, including Lee Chadwick, Louis Renault, and Gottlieb Daimler, also experimented successfully with what would later become known as supercharging systems.

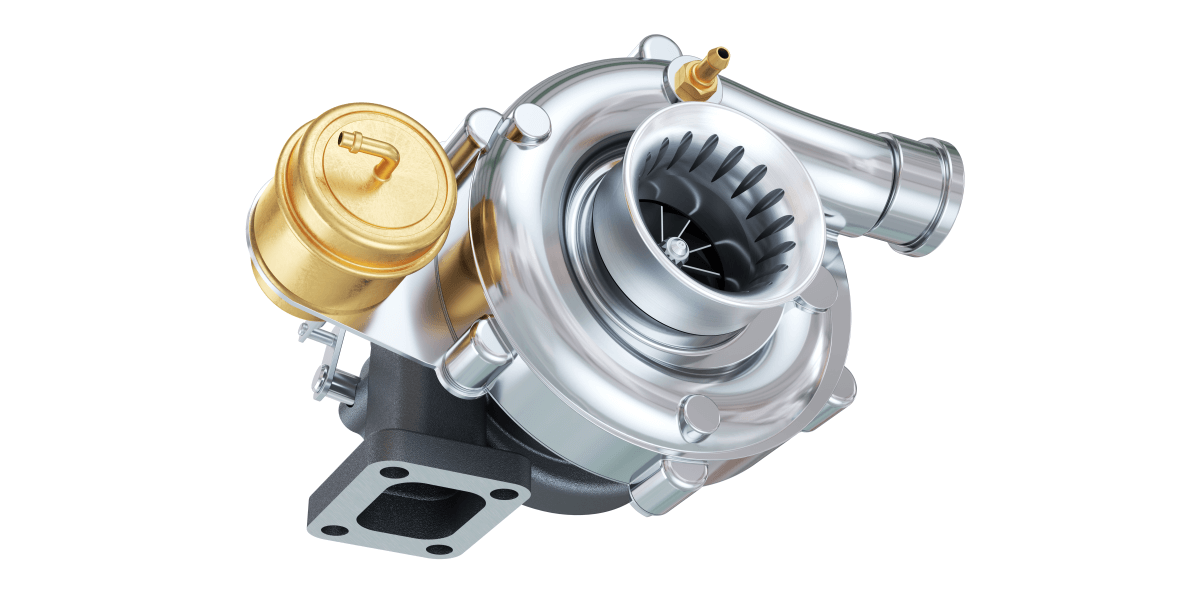

What Are Turbochargers?

Turbochargers, just like superchargers, are forced induction systems. They can boost horsepower without drastically increasing a vehicle's weight. In short, turbochargers increase airflow into the engine, increasing the amount of air that can be squeezed into a cylinder, thus allowing more fuel to be injected. Such a process consequently results in more efficient use of the energy created by the explosions in the cylinders, ultimately producing a higher power output.

How Do Turbochargers Work?

As stated above, turbochargers allow for the squeeze of more air and fuel into the cylinders. To do so, the turbocharger harnesses the airflow from the exhaust to power the turbine. The more air that passes through, the faster the turbine spins. Typically, with most OEM factory-installed turbocharging systems, the boost a turbocharger gives to an engine is around 6 to 8 psi. Given that the normal atmospheric pressure at sea level is 14.7 psi, the boost the turbocharger provides is approximately packing 50% more air into the engine's cylinders. However, the system is not 100% efficient. A 50% increase in air intake does not translate into 50% more power. At best, you might get 30 to 40% more power.

The inefficiency in the system comes from the fact that the power that the turbocharger creates does not go 100% into powering the engine. The turbine in the exhaust flow restricts the exhaust, causing more resistance, which means that the engine has to push against a higher back pressure on the exhaust stroke, which takes away a bit of the power from the cylinders that are firing simultaneously.

Turbocharging 101

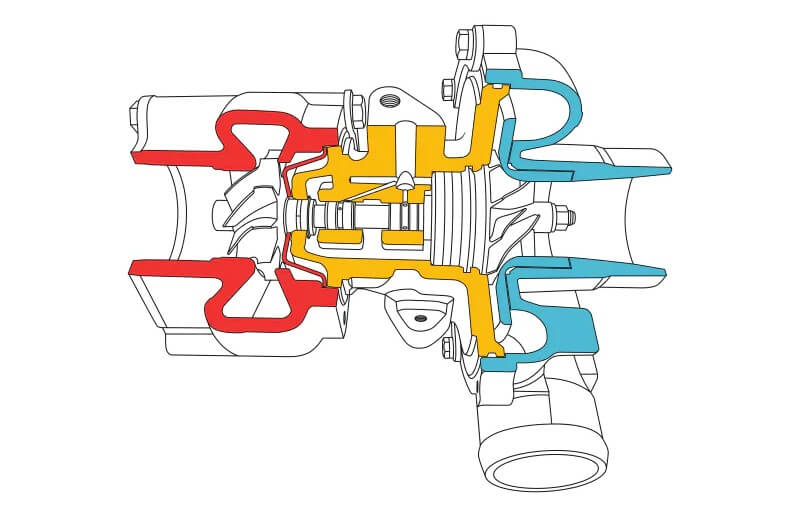

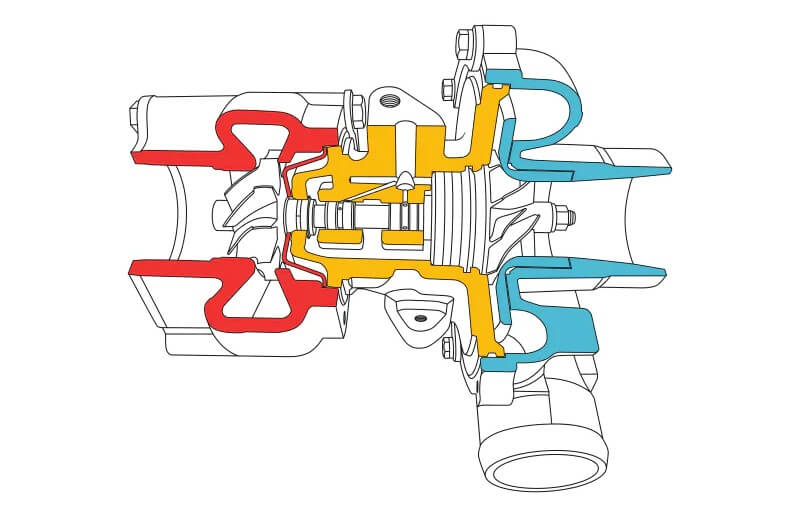

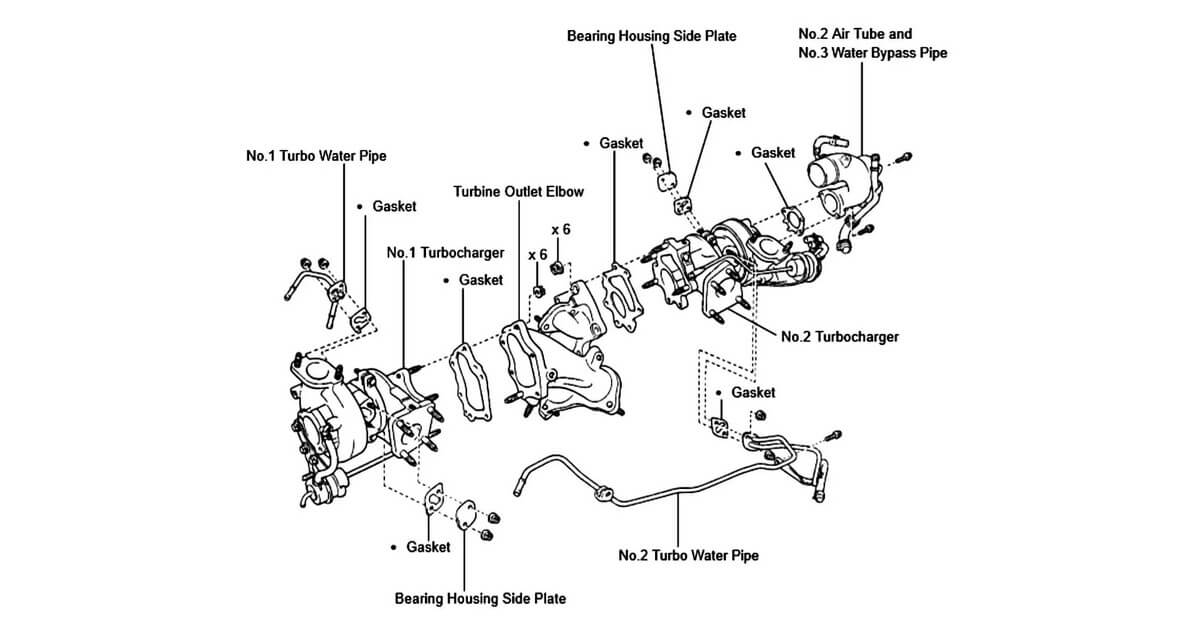

The turbocharger is located on the exhaust manifold to which it is bolted. The exhaust gases from the cylinders power the turbine, also called the "hot side." A shaft joins the turbine and the compressor, making them spin together at all times. As the turbine turns, the compressor pressurizes the air flowing to the pistons as it sits between the intake manifold and the air filter. The compressor draws air into the center of the blades and flings it outward as it spins, just like a centrifugal pump.

Many turbochargers use fluid bearings, while others use ball bearings. A fluid bearing holds the shaft, continually bathed in a thin layer of oil. Additionally, it cools the moving parts and allows the shaft to spin with minimal friction. However, ball bearings allow less friction on the turbine shaft than the fluid bearings found in most turbochargers. They also allow a lighter, smaller shaft to be employed, improving and quickening acceleration in the turbocharger, further reducing lag. Most turbochargers use ceramic turbine blades, which are lighter than steel blades.

Other Important Components of Turbocharging Systems

Wastegate

Many turbochargers are equipped with a wastegate, a valve that diverts exhaust gases away from the turbine fan. Diverting the extra exhaust gases helps regulate the turbine fan's speed, which in turn regulates the compressor's rotation speed. This allows for the use of a smaller turbocharger without running into low-boost problems.

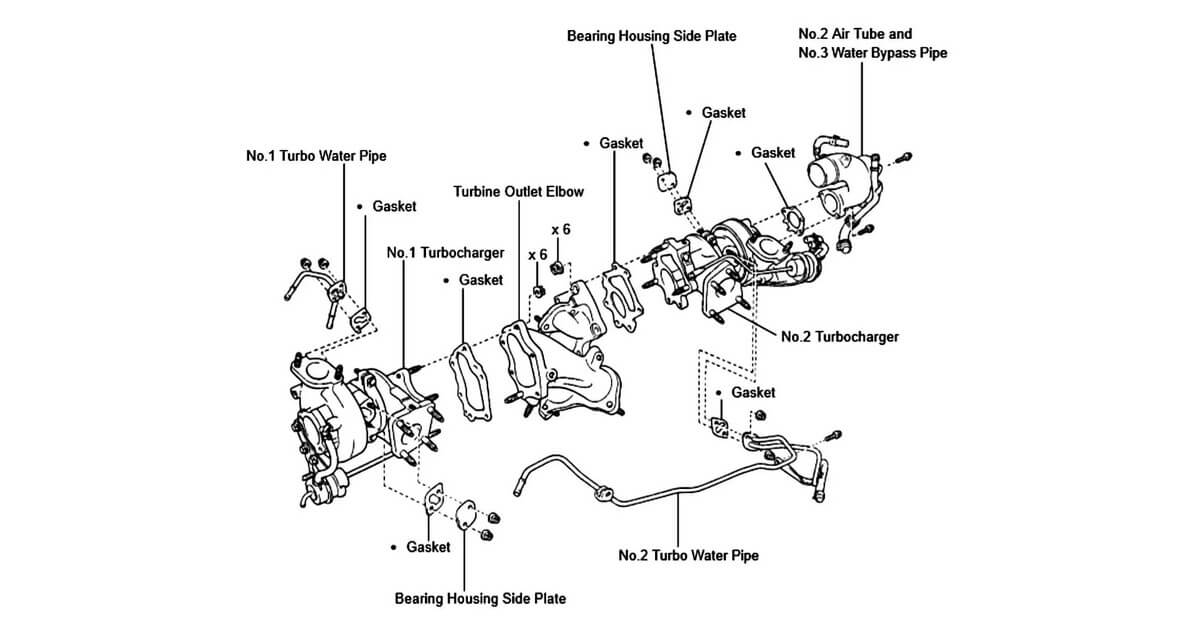

On most vehicles equipped with a wastegate, a pressure sensor trips the wastegate when the turbine is spinning too fast. Some engines have two turbochargers of varying sizes. Smaller ones can get up to speed rapidly, while larger ones kick in at higher speeds, thus providing a continual boost.

Intercooler

An additional component is an intercooler or charge air cooler, which resembles and acts like a radiator, except that air passes through both the inside and the outside of the intercooler. Cooler air is denser with oxygen than hot air. Since oxygen is one of the main elements required for combustion to occur, cooler air will also increase the output power produced by the engine.

That is when intercoolers come in handy. The cooler air from outside is blown across the fins and cools down the intake air passing through the intercooler. Some high-performance race cars even use a nitrous oxide system to spray freezing nitrous directly onto the intercooler to cool down the air even more.

O2 Sensors

Older cars that still have carburetors will automatically increase the fuel amount to match the airflow going into the cylinders. However, modern vehicles with fuel injection systems rely on oxygen sensors to evaluate and adjust the air/fuel ratio. When installing a turbo on a naturally aspirated car, replacing the O2 sensors with wide-band O2 sensors capable of handling the higher airflow is sometimes required.

Fuel System

The same applies to the fuel pump. If a turbocharger produces too much boost, the system may have a hard time injecting enough fuel. In that case, installing a high-flow fuel pump and injectors will be required.

Drawbacks of Turbocharged Engines

With turbocharged engines, there's a higher chance of engine knocking. Knocking can occur as the compressed air's temperature rises. If the temperature increases enough, it can cause the fuel to prematurely ignite in the piston before the spark plug fires. This is one of the reasons why manufacturers recommend running turbo vehicles on high-octane fuel: to prevent engine knocking.

A downside that tends to plague turbochargers is that boost is not instantaneous when pressing the gas pedal. The response is always slightly delayed because the turbine needs to build up speed before a boost is felt, which can cause the car to jolt when the turbo boost kicks in.

To decrease the "lag," the inertia of the rotating parts can be decreased. The simplest way of achieving this is by reducing their weight. Reducing the weight allows the turbine and compressor to accelerate more rapidly, thus providing an earlier power boost. Another way to reduce the power boost delay is to make the turbocharger smaller. The decrease in the size of the turbocharger is another way of lowering the inertia in the moving parts. It will help provide a power boost more rapidly at lower engine speeds. The trade-off to reducing inertia is that, at higher speeds, a smaller turbine may be unable to keep up, resulting in a weaker power boost due to the turbine fan spinning too fast.

Frequently Asked Questions (FAQ)

Q: Can I install a turbocharger on any car?

Yes, you can install a turbocharger on almost any car, but significant modifications to the engine and exhaust systems are required. To avoid damage, it's important to ensure that the engine can handle the increased pressure and heat generated by the turbocharger.

Q: How often should I maintain a turbocharged engine?

Turbocharged engines require more frequent maintenance than naturally aspirated engines. Regular oil changes, air filter replacements, and monitoring of the turbo system components are essential to keeping the turbocharger in good condition and preventing failures.

Q: What are the signs of a failing turbocharger?

Common signs of a failing turbocharger include excessive exhaust smoke, loss of power, unusual noises (such as whining or grinding), and oil leaks. If you notice any of these symptoms, it's essential to have your turbo system inspected.

Q: Can a turbocharger improve fuel efficiency?

Yes, a turbocharger can improve fuel efficiency by allowing a smaller engine to produce more power, reducing the vehicle's overall weight and drag. However, if driven aggressively, turbochargers can definitely lead to increased fuel consumption.

Q: Is it necessary to let the engine idle before turning it off after driving with a turbo?

Yes, it's recommended to let the engine idle for a minute or two before shutting it off after driving with a turbo. This allows the turbocharger to cool down and the oil to circulate, preventing potential damage to the turbo's bearings.

Last Words

Turbocharging systems are becoming increasingly popular and more common on stock vehicles. In the race to produce the most fuel-efficient cars possible, car manufacturers are turning to turbochargers as a quick and effective way to reduce engine size while maintaining satisfactory performance. By forcing more air into the engine, turbochargers allow smaller engines to produce more power, aligning with the industry's goals for efficiency and performance.

However, turbos come with their own set of challenges. They are expensive to install and maintain and prone to failure if not properly cared for. Issues like turbo lag and engine knocking can detract from the driving experience and lead to costly repairs.

Understanding how a turbocharger works and learning how to troubleshoot and fix common turbo problems can be your best strategy to save on expensive forced-induction system repairs. Hence, by investing a little time in education and regular maintenance, you can enjoy the benefits of a turbocharged engine while minimizing the downsides.