Ever since the dawn of the automotive age, car engineers tried to incorporate the latest technology in cars as much as they can. The rise of electronic devices found a perfect place in the car industry. It improved the performance and power output while reducing harmful emissions, making cars faster, safer, and more environmentally friendly. A good example of a component that had a significant impact on automotive technology is the oxygen sensor, an integral part of every modern car. This little electronic device plays an important role in the proper functioning of your vehicle. Obviously, such a vital device is bound to create troubles when it goes bad. To help you quickly find the source of the problem, we have created this article covering what is an O2 sensor and what happens when it's faulty as well as how to test one and replace it when needed.

What is an O2 Sensor, and What is it Used For?

The O2 sensor, also sometimes called oxygen, Lambda sensor, or HO2S in the case of heated models, is an electronic device that precisely measures the oxygen level in the engine's exhaust fumes. The primary purpose of the oxygen sensor is to monitor if the engine is burning fuel correctly and send the information about the oxygen level contained in the exhaust gases back to the PCM. It's needed to determine if the fuel-air mixture is correct and see if the catalytic converters are doing their job properly.

In case the O2 sensor reports a high or low amount of oxygen in the exhaust gasses, the information is sent to the PCM, which can then adjust the fuel-air mixture by modifying the injectors' opening time accordingly. If the readings stay out of a certain threshold for a certain amount of time, the PCM will record a DTC code and turn on the check engine signal, suggesting that there is a bigger problem with the engine's combustion cycle.

Different Types of O2 Sensors:

Even though all O2 sensors do the same job, there are several distinctive types on the market. Here's the three most common variants:

Zirconia O2 Sensor

This is the most common type of oxygen sensor and is found in most modern vehicles. It also comes in two sub-types – heated and unheated.

Heated models

For an O2 sensor to work properly, it needs to have reached a specific operating temperature. As long as they are cold, the engine runs based on default settings and doesn't take into account the readings from the sensors. During the warm-up time, engines will typically run rich, which results in higher fuel consumption and greater toxic emissions.

Unheated models

Unheated models are simply bolted onto the exhaust and only send readings after they have reached the right temperature. On the other hand, heated Zirconia sensors have a built-in heater so they can start sending data a lot quicker, reducing the amount of time required for the engine to work as optimally as possible.

Titania O2 Sensor

This type of sensor uses titanium oxide instead of zirconia oxide as well as different voltage. It was used in some older vehicles, and now it is almost entirely abandoned.

Wideband O2 Sensor

Introduced in the mid-'90s, wideband O2 sensors are the latest and best in the business. Their advantage lies in their advanced design and upgraded sensitivity and faster communication with the PCM. Wideband sensors can measure the exact air/fuel ratio instead of simply switching from "too-rich" and "too-lean". This type of sensor used to be mostly used in high-end performance vehicles and for race applications but it is found more frequently on recent vehicles these days.

Difference Between Front and Back O2 Sensors

Even though front sensors (B1/S1) and back (B1/S2) sensors are identical in terms of construction and serve the same purpose, their position is crucial.

B1/S1

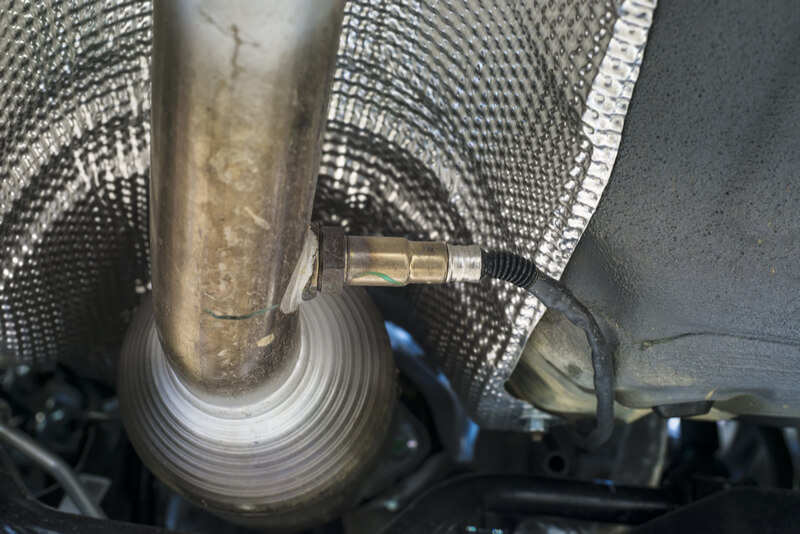

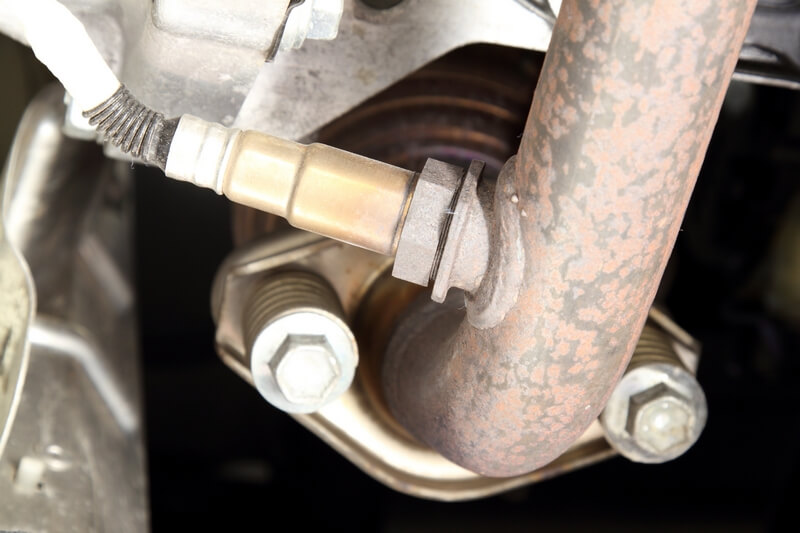

The front one is mounted on the exhaust manifold, directly after the combustion chambers and measures exhaust fumes as soon as they exit the engine and before they arrive at the first catalytic converter. Their job is to detect if something is wrong with the air/fuel ratio.

B1/S2

The second one, or S2, is mounted after the catalytic converters its job is to determine if the converters properly did their job. For example, if the B1/S2 detected an anomaly, the PCM will start by comparing the data to the B1/S1. If everything looks good with the B1/S1, it will know that something is wrong with the catalytic converters and will record a specific cat-related DTC code. On the other hand, if it detects that the B1/S1 is also sending incorrect data, the problem might be combustion-related, and one of the injectors might be faulty or a spark plug might be busted.

Both sensors have their use and understanding which one does what will help you quickly identify the source of O2 sensors-related DTC codes.

Difference Between B1 and B2 Sensors

When you have straight-four or straight-six engine, you only need two O2 sensors per exhaust manifold, one before and one after the catalytic converters. However, when you have a V6, V8, or even a flat-four or flat-six engine, there is a need for four sensors, two for each cylinders bank. That is why there are B1 and B2 sensors.

The "B" stands for "Bank" or engine side. Although they serve the same purpose and are identical, the B1 and B2 sensors are not always interchangeable because of the different configuration of their connectors. Why you may ask? You'd have to ask that to the engineer working at your car's manufacturer. I'd be really eager to hear what they have to say about it too! lol

Most Common Symptoms of Bad O2 Sensors

Although O2 sensors are quite durable and pretty straightforward, they have their limitations and are known to fail after some time. Don't forget that they are bolted right onto the exhaust manifold and, therefore, have to withstand extreme temperatures. Here are the most common symptoms of a faulty O2S and how to spot them.

Check Engine

As soon as the PCM detects that a sensor may be sending out-of-threshold data, it will revert to its default settings. That is why the most common symptoms of a bad O2 sensor is a check engine light. In most cases, even if both sensors are burnt beyond recognition, the engine will continue working as if nothing happened.

When it happens, the first thing to do is to hook your car up with a good OBD2 scan tool to learn more about the code. The DTC code description will usually give you a good idea of what the problem is and what you need to do to troubleshoot it.

Rough Idle

An O2 sensor will sometimes start by failing intermittently or by sending slight off data. When it happens, the PCM may try to correct the air/fuel ratio, which will then result in a rough idle, misfires, and jerky accelerations.

Poor Gas Mileage

Once again, as O2 sensors mostly control the amount of fuel sent into the engine, a big giveaway of a bad HO2S is a significant increase in fuel consumption. A faulty O2 sensor will provide the PCM with false readings, often resulting in more fuel in the mixture. The engine will start to run rich and will use a lot more fuel as a result.

Most Common O2 Sensor-Related DTC Code

For those who have access to an OBD2 scan tool, which is almost always necessary for this type of troubleshooting, it is essential to know which DTC codes are related to O2 sensors and what they mean.

Also, in some cases, a code may be recorded, but in fact, the problem will be related to another subsequent problem, like an exhaust leak or a bad catalytic converter. Since their job is to monitor the air/fuel ratio, any faulty component that may have an impact on the stoichiometric ratio may record a code. Always makes sure to fix other codes present in the PCM before focusing on an O2 sensor-related DTC code. In most cases, fixing your P0300-P0304 misfire code will also fix that P0172 System Too Rich code too.

P0030-P0064

These codes are related to the heater side of the O2 sensors. You can test the heater for continuity and if it's open loop, the sensor will need to be replaced. On the other hand, if there's continuity, the heater's control circuit may be open or short-to-ground or the PCM might not be sending power.

P0130-P0175

These are all the other codes related to any malfunction that could happen with an O2 sensor. In most cases, the code's description will give you a good idea of where to start. When in doubt, you can always look for more info and specific troubleshooting procedures in your car's repair manual.

How to Test an O2 Sensor Depending on the Type

The main problem with determining if an HO2S is really broken is their symptoms are similar to many other engine problems. In order to be sure, you'll need to properly test the O2 sensor.

Of course, you'll need a digital multimeter to do that.

Instructions:

- Locate the O2 Sensor – On recent vehicles, there always one before the first catalytic converter and one after the second one. Older cars only have one on the exhaust manifold.

- Identify the wires – Single wire sensors are the easiest to connect, but for the rest (two, three, four-wires) be sure to identify the wire which you want to check. Make sure you differentiate the data and ground wire from the heater control circuit wires. When in doubt, make sure to check at the sensor's wiring diagrams in your car's repair manual.

- The Vehicle Should be Warmed Up at Operating Temperature – You can leave it at idle for a couple of minutes or take it for a short drive. Watch the exhaust manifold. It will be hot as hell!

- Turn Off the Engine and Connect the Voltmeter to the Appropriate Wires

- Start Engine and Check the Voltmeter Readings – If you're checking the sensor side and the readings are between 100 mV to 900 mV, the sensor is working correctly. If the readings are way off, you know it's faulty.

On the other hand, if you are testing the heater side, you should test it for continuity. The acceptable values will differ depending on the car model so make sure to check the right threshold for your vehicle in the repair manual.

O2 Sensor Replacement Cost

Depending on the make and model, O2 sensor replacement can cost you from $50 all the way to several hundred dollars. Although the part itself is relatively cheap and HO2S start at around $50, most modern cars have advanced sensors, which can cost as much as $400, especially wideband ones.

If you have your O2 sensor replaced at a repair shop, labor should also be taken into consideration. Most repair shops will usually charge around an hour of work to replace one.

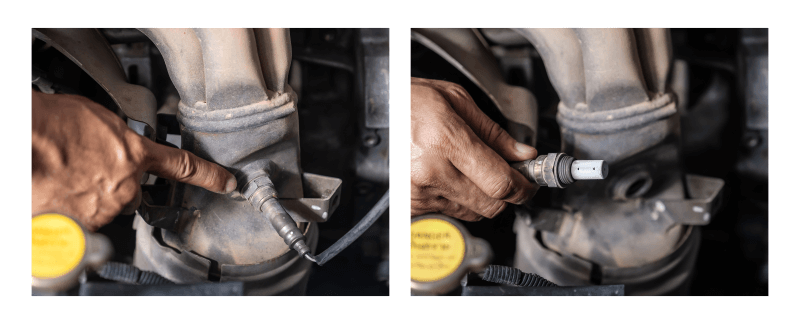

DIY

Obviously, the easiest way to save money on your O2 sensor replacement is to do the job yourself. Luckily, most oxygen sensors are quite easy to access and replace. In most cases, all you have to do is to unplug and unscrew it from the exhaust. Unfortunately, since they are positioned on one of the hottest components aside from the engine itself, it's not uncommon that they seize in place. When it happens, you'll need heat the exhaust with a torch before removing it or you might strip the treads.

Frequently Asked Questions (FAQ)

How often should I replace my O2 sensor?

Oxygen sensors typically last anywhere between 60,000 and 90,000 miles, depending on your vehicle and driving conditions. However, it’s always good practice to check them if you notice any common symptoms like poor gas mileage or a check engine light.

Can I drive with a faulty O2 sensor?

Yes, you can technically drive with a faulty O2 sensor, but it’s not recommended. It may cause the engine to run rich or lean, leading to increased emissions, poor fuel efficiency, and even potential damage to your catalytic converter over time.

What tools do I need to test an O2 sensor?

To test an O2 sensor, you’ll need a digital multimeter, and possibly access to your car’s repair manual for wiring diagrams. It’s a straightforward test but remember, safety first—exhausts get extremely hot!

Are aftermarket O2 sensors reliable?

Aftermarket sensors can be reliable, but it’s always safer to stick with OEM parts or a trusted brand. Cheap knockoffs can fail prematurely or give inaccurate readings, leading to more headaches down the road.

Is replacing an O2 sensor a DIY job?

In most cases, yes. As long as the sensor isn't seized up in the exhaust, replacing it is usually a straightforward process. Just unplug it, unscrew it, and install the new one. If it’s stuck, a torch might be needed to loosen it up, so be prepared for that.

The Critical Role of the O2 Sensor in Your Engine

The O2 sensor may be small in size, but it plays a monumental role in how your engine performs. Without it, the precision that modern engines achieve in power, fuel efficiency, and emission control would be impossible. Over the past few decades, the oxygen sensor has evolved from a simple component to a critical part of every new internal combustion engine, ensuring that vehicles meet the ever-stricter standards for emissions and performance.

Despite its high-tech function, troubleshooting and replacing an O2 sensor is relatively straightforward. When in doubt, following the manufacturer’s recommended procedures in your vehicle’s repair manual will guide you through the process, ensuring you keep this vital part working as intended. So, the next time your check engine light comes on, don’t underestimate the power of this little sensor—it’s doing more for your car than you might think.