Keeping a semi-truck on the road with smooth, reliable handling starts with solid, well-maintained tie rods. Although small, tie rods are crucial to the steering system, linking the steering wheel to the front wheels. Without tie rods in top shape, steering can feel loose or unpredictable, creating risks for the driver—especially when hauling heavy loads over long distances.

If you’re noticing wobbly steering, uneven tire wear, or vibrations at highway speeds, it’s likely time to check your tie rods. I’ve seen plenty of these symptoms point to worn tie rods, especially in trucks that clock high miles on rough terrain. Replacing semi-truck tie rods might seem like a big task, but with the right steps and a few tools, it’s something you can tackle yourself. This guide will cover everything you need to know, from diagnosing wear to removing and replacing tie rods. We’ll go through the essentials, like required tools, signs of wear, and maintenance tips.

By the end, you’ll have the knowledge to handle this job yourself and understand how this one repair can improve your truck’s safety and performance.

Let’s get started.

Understanding Tie Rods in Semi Trucks: Function, Types, and Components

Before getting into replacement, it’s worth knowing how tie rods work, why they matter, and what parts make up the assembly. In a semi-truck, tie rods are essential—they keep the front wheels aligned and responsive to your steering. Let’s break down their role, types, and key components.

Function of Tie Rods in Semi-Trucks

Tie rods connect the steering gearbox to the front wheels. When you turn the wheel, the tie rods adjust the angle of the wheels, helping you steer a truck that’s built to handle heavy loads and rough roads. Properly functioning tie rods keep the wheels aligned—parallel and straight ahead. This alignment is critical for smooth handling, even tire wear, and reducing maintenance costs. Worn tie rods allow the wheels to drift out of alignment, leading to poor handling and more serious issues with the steering and suspension.

Types of Tie Rods

Most semi-trucks have two main types of tie rods — inner and outer.

Type |

Location |

Function |

Wear Factors |

Inner Tie Rods |

Closer to the steering gearbox |

Transmit movement from the steering wheel to the outer tie rods |

Protected by a sleeve; less exposure to elements |

Outer Tie Rods |

Closest to the wheels |

Directly influence wheel angle and direction |

Exposed to road elements; higher wear from movement |

Some trucks also have center links or drag links that help connect both tie rods in specific steering systems, but for most repairs, focusing on inner and outer tie rods will cover the basics.

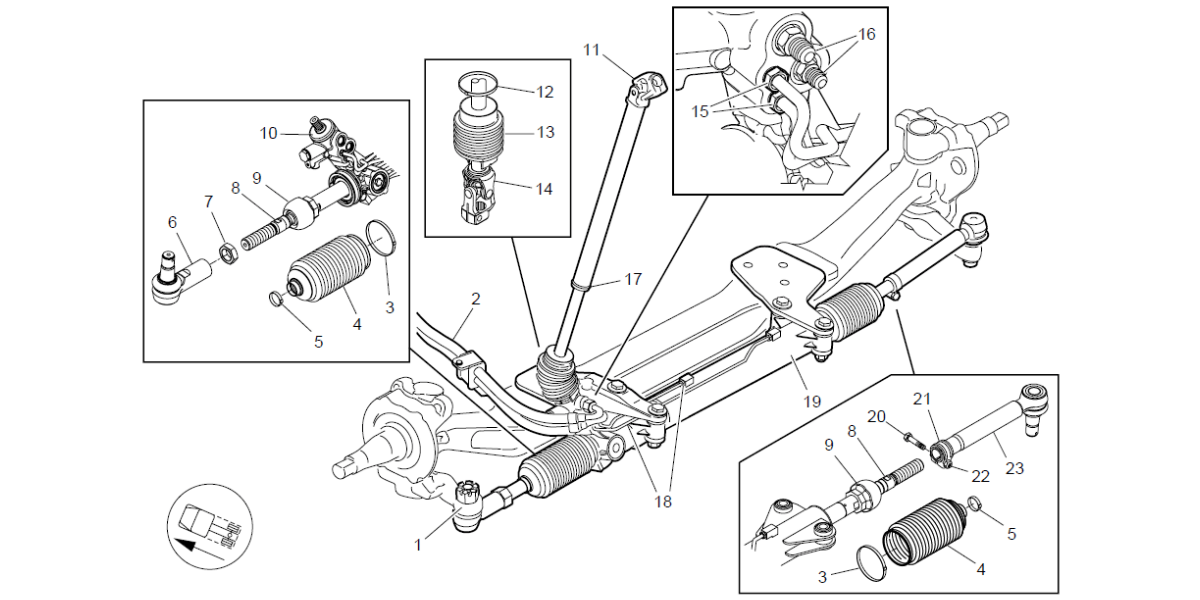

Components of a Tie Rod Assembly

Tie rod assemblies are built for continuous movement and pressure. Key parts include:

- Tie Rod Ends: Threaded ends that link the tie rod to the steering system and wheel hub, allowing the wheels to pivot and steer. They typically feature ball-and-socket joints for flexibility.

- Ball Joints: Located at the tie rod ends, ball joints allow the steering to adjust to uneven surfaces. They take a lot of stress and can wear over time, leading to loose or unresponsive steering.

- Adjuster Sleeves: These threaded sleeves connect inner and outer tie rods, letting you make small adjustments to wheel alignment.

- Protective Boots: Rubber or plastic boots protect the tie rods from dirt and moisture. If a boot is cracked or torn, it’s best to replace it to avoid wear on the inner components.

These components work together to keep your truck steering accurately. As we go through the replacement steps, we’ll reference these parts to help you understand each step and why it matters.

How to Diagnose Worn or Failing Tie Rods in Semi Trucks

When a truck rolls into the shop with steering complaints, tie rods are one of the first things I check—catching early signs of wear keeps costs down and prevents steering headaches on the road. If you’re noticing steering vibration or uneven tire wear, those are dead giveaways that tie rods might be the culprit. Here’s how to spot the telltale signs and avoid a bigger fix later.

Inspection Techniques for Tie Rods

If you suspect wear, start with a quick visual and physical inspection. Here’s what to do:

- Safety First: Park on level ground, engage the brakes, and chock the wheels.

- Access the Front Wheels: Use a jack to lift the truck’s front end, securing it with heavy-duty jack stands.

- Visual Check: Inspect tie rod ends, ball joints, and adjuster sleeves for cracks, torn boots, rust, or corrosion. Damage to the boots allows dirt in, which accelerates wear.

- Shake Test: Grab each front wheel at the 3 and 9 o’clock positions and try to move it back and forth. If you feel noticeable play or hear a knocking sound, the tie rods may be worn.

- Joint Flexibility Check: Use a pry bar if needed to check the tie rod ends. They should feel firm, with minimal play. Loose joints signal it’s time for replacement.

Common Symptoms of Worn Tie Rods

Not all tie rod issues are visible; here are signs to watch for while driving:

- Steering Vibration: Loose tie rods cause the steering wheel to shake, especially at higher speeds.

- Uneven Tire Wear: Misalignment from loose tie rods shows up as uneven wear on tire edges.

- Wobbly Steering: If the steering feels loose or delayed, it could mean the tie rods need attention.

- Pulling to One Side: Worn tie rods can throw off alignment, causing the truck to pull.

- Clunking or Knocking Noises: Listen for these sounds, especially when turning or driving over bumps—they’re often a clear indicator of failing tie rods.

When to Replace vs. Monitor

Once you’ve inspected and diagnosed, the next step is determining whether replacement is necessary. Replace tie rods immediately if you find visible damage, significant play, or experience steering instability. For minor wear without noticeable impact on handling, regular monitoring can be sufficient, especially if the truck frequently encounters rough terrain or heavy loads.

Regardless, regular inspections help catch early signs of wear and keep your truck handling smoothly.

How to Replace Tie Rods on a Semi Truck: A Step-by-Step Guide

Replacing tie rods on a semi-truck might seem challenging, but with the right tools and steps, it’s doable. Let’s dive into the process of replacing semi-truck tie rods, with clear, detailed steps to ensure accuracy and safety.

Preparation and Tools Needed

Gather the following tools to ensure a smooth replacement process:

- Jack and Jack Stands: Rated for a semi-truck’s weight

- Wheel Chocks: For stability

- Socket Set and Adjustable Wrench: For bolts and tie rod ends

- Torque Wrench: Essential for precise tightening (don’t eyeball it; trust me here)

- Pry Bar and Penetrating Oil: Helpful for loosening corroded parts

- Grease Gun: For lubricating new tie rods

- Marker or Tape: To mark alignment settings

- New Tie Rods: Specific to your truck model

Once ready, park on a level surface, engage the parking brake, and chock the rear wheels. Approach each step carefully if this is your first replacement.

Step 1: Lifting and Securing the Vehicle

- Position the Jack: Make sure to place the jack under a secure lifting point on the front axle rated for the truck’s weight—don’t cut corners here. The last thing you want is a shift or wobble while you’re under the truck. Use heavy-duty jack stands and double-check stability before you even think about reaching for the tie rods.

- Raise the Truck: Lift it until the front wheels are off the ground.

- Set Jack Stands: Securely place jack stands under the truck for added stability. Never rely solely on the jack.

- Check Stability: Ensure the truck is steady on the stands before proceeding.

Step 2: Locating and Accessing the Tie Rods

- Find the Tie Rod Assembly: Follow the steering linkage from the steering box to the wheel hub.

- Remove Covers or Shields: If there are protective shields, use a wrench to remove any bolts holding them in place.

- Mark the Adjuster Sleeve Position: Use a marker or tape to mark the current alignment on the adjuster sleeve. This will aid in alignment when installing the new tie rods.

Step 3: Removing the Old Tie Rods

- Loosen the Lock Nut: Use an adjustable wrench to loosen the lock nut on the adjuster sleeve, applying penetrating oil if needed.

- Detach the Tie Rod Ends: Remove any cotter pins and loosen the nut holding the tie rod end to the wheel hub. Carefully pry the tie rod end out of its connection point.

- Unscrew the Tie Rod Assembly: Note the number of turns it takes to remove the tie rod, as this will help keep alignment when installing the new one.

- Repeat on Both Sides: If replacing both tie rods, repeat these steps on the other side.

Step 4: Installing the New Tie Rods

- Thread the New Tie Rod: Insert it into the adjuster sleeve, matching the turn count from removal to help maintain alignment.

- Attach the Tie Rod End to the Wheel Hub: Secure it with the nut, tightening to the manufacturer’s torque specifications.

- Tighten the Lock Nut: Ensure the tie rod is firmly secured and won’t move over time.

- Lubricate: Use a grease gun on any fittings if the new tie rods aren’t pre-lubricated.

Step 5: Ensuring Proper Alignment After Replacement

- Lower the Truck and Re-check Alignment Marks: Lower the truck and verify that the marks on the adjuster sleeve are still aligned.

- Perform a Basic Alignment Check: Take the truck for a short drive to check for any pulling or misalignment. Minor adjustments to the adjuster sleeve may help, but a professional alignment is recommended for accuracy.

- Test Drive for Steering Response: Test drive the truck, paying attention to steering response and handling. If the steering feels tight and responsive, the job is complete.

Indeed, replacing semi-truck tie rods takes time and patience, but following these steps ensures a safe, effective job. Properly installed tie rods improve control and prevent alignment and tire wear issues, making the effort well worth it.

Maintenance Tips for Extending the Life of Semi Truck Tie Rods

Routine maintenance of your tie rods is key to keeping your truck handling smoothly and avoiding unexpected breakdowns. With a few regular checks and adjustments, you can significantly extend the life of your tie rods and protect your steering system from premature wear.

Start with Regular Visual Inspections

Adding a quick visual check to your maintenance routine can catch early signs of wear and tear. Examine the protective boots on the tie rods for cracks or tears; these boots keep out dirt and moisture, and damage to them can speed up wear on the inner components. Rust or corrosion is another red flag that suggests metal deterioration, especially if your routes often expose the truck to road salt or extreme weather. Finally, give the tie rod ends a quick manual check—if they feel loose or have a noticeable play, replacement might be on the horizon.

Lubricate Tie Rod Ends Consistently

Like most moving parts, tie rods benefit from regular greasing to reduce friction and wear. Using a grease gun, apply heavy-duty, high-temperature grease every few thousand miles to the zerk fittings on the tie rods. While it’s important to keep the joint moving smoothly, avoid over-greasing, as this can stretch or even tear the boot. A few pumps are generally enough to keep things in order.

Schedule Routine Alignment Checks

Wheel alignment plays a huge role in the longevity of tie rods. Misalignment adds stress and can wear them down faster, so an annual professional alignment is a smart investment, particularly for trucks that carry heavy loads or travel rough terrain regularly. After any major repair to the steering or suspension system, realigning the wheels keeps everything balanced. In between professional checks, stay alert for signs of misalignment, such as a crooked steering wheel or the truck pulling to one side—early corrections prevent more stress on the tie rods.

Drive Smoothly to Minimize Impact Stress

How you drive also affects tie rod life. Steering systems take a lot of wear, so handling the truck with care can make a difference. Avoid driving over curbs and large potholes, as these can bend or misalign the tie rods, causing premature wear. On rough or unpaved roads, slow down to reduce strain on the steering. Smooth, controlled steering, especially when the truck is loaded, helps reduce unnecessary stress on the tie rods, ultimately extending their lifespan.

Replace Worn Components Promptly

Because tie rods work closely with other steering components, keeping everything in good shape helps the whole system last longer. If you notice worn parts like ball joints or control arms, replace them promptly; failing to do so can increase stress on the tie rods. When replacing tie rods, it’s often a good idea to replace both sides at once—semi-trucks need balanced steering to handle optimally, and replacing components in pairs ensures even wear. For trucks in challenging conditions, having spare tie rods handy helps avoid downtime if a repair is needed on the road.

Monitor Steering Feel and Response

Often, the first sign of tie rod wear is a subtle change in how the truck steers. Pay attention to any increased play or looseness in the steering wheel; if you find yourself needing to correct more frequently to keep straight, your tie rods may be wearing out. Listen for any clicking, clunking, or knocking sounds from the front end, especially when making turns or driving over bumps—these noises often signal that a tie rod joint is loose or failing. Addressing these early signs keeps your steering system secure and your truck safe on the road.

Following these maintenance tips will help keep your tie rods, and overall steering system, in top condition. A little attention to these details now means better control, safer handling, and less downtime in the long run.

Frequently Asked Questions (FAQs)

How do I know if my semi-truck’s tie rods are bad?

If your tie rods are wearing out, you’ll likely notice symptoms like wobbly or loose steering, a pulling sensation to one side, or unusual vibrations while driving. You may also see uneven tire wear, hear clunking or knocking sounds when turning, or feel increased play in the steering wheel. Regular checks can catch these signs before they lead to bigger issues.

How often should tie rods be replaced on a semi-truck?

There’s no set schedule, as it depends on driving conditions, load weight, and road quality. Tie rods can last anywhere from 100,000 to 150,000 miles, but if your truck is frequently on rough roads or hauling heavy loads, they may wear out faster. Regular inspections are key to catching wear early.

Can I replace semi-truck tie rods myself, or do I need a mechanic?

If you’re comfortable with tools and have some experience with truck maintenance, replacing tie rods is manageable as a DIY job. Follow a detailed, step-by-step guide to ensure proper alignment and torque. That said, if you’re unsure about alignment after the replacement, it’s worth having a mechanic check it.

What happens if I don’t replace bad tie rods?

Ignoring worn tie rods can lead to serious problems. They’re essential for keeping the front wheels aligned and steering precise. Bad tie rods throw off alignment, causing uneven tire wear, steering instability, and, in worst cases, a complete loss of control while driving. Replacing them promptly keeps your truck handling safely and smoothly.

How much does it cost to replace tie rods on a semi-truck?

The cost varies, but on average, parts and labor can range from $300 to $800 per side if done by a professional. DIY replacement saves labor costs but still requires quality tie rods and the right tools. Remember to factor in an alignment check afterward, which ensures everything’s balanced and aligned properly.

The Lasting Impact of Tie Rod Replacement and Maintenance

Keeping a semi-truck’s steering system in top shape is both super important and beneficial. A well-maintained set of tie rods goes a long way, reducing tire wear, minimizing alignment issues, and preventing breakdowns that throw a wrench in your schedule and your bottom line. Taking time to inspect, maintain, or replace worn tie rods puts you in the driver’s seat, extending the life of your truck and giving you the peace of mind that you’re ready for the road ahead.

So, keep those tie rods in check, and keep rolling with confidence, knowing your rig’s steering system is up to the journey's demands.