Modern cars use a serpentine belt to drive accessories. The serpentine belt is a critical component; without it, the water pump and alternator cannot function properly. A car will quickly overheat and the battery will die out when its serpentine belt fails. Luckily, inspecting serpentine belts and replacing them at home is an easy task that doesn't require a lot of know-how or special tools. To help you with that, here's what a serpentine belt is, how it works, and how to replace it and save a bunch of money on expensive repair shop bills at the same time.

What is a Serpentine Belt?

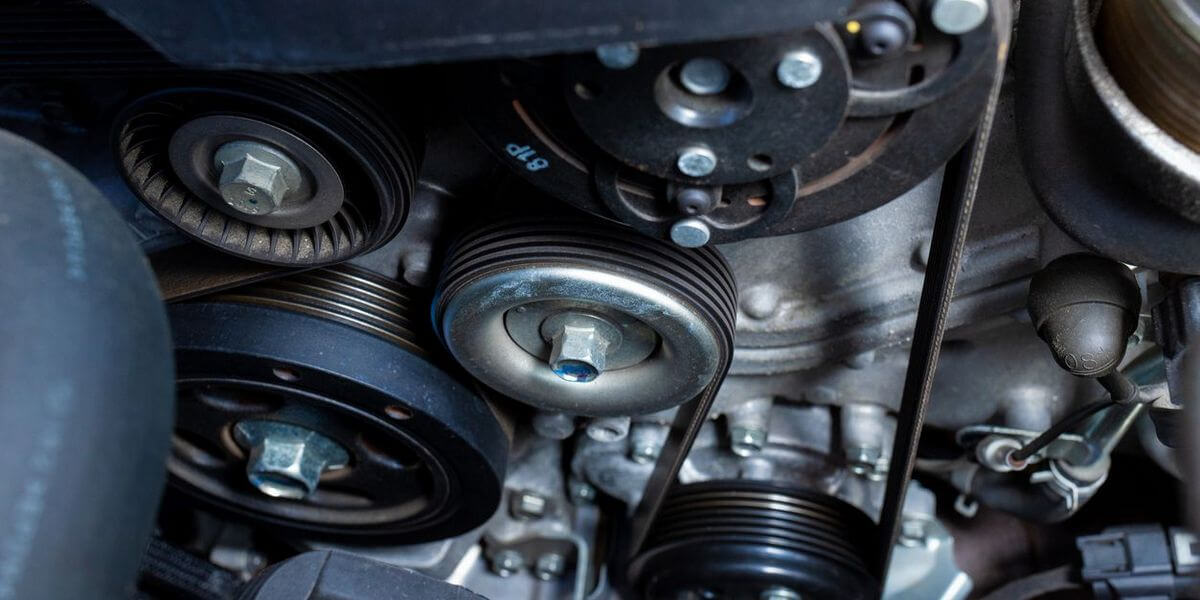

The serpentine belt is a rubber belt on the front of the engine. It connects and provides rotational power for various accessories. Serpentine belts have become common an all cars and trucks since the 1980s, effectively replacing V-belts as the standard equipment to power engine accessories.

The serpentine belt is so-called because of the snaking manner in which the belt makes contact with pulleys on engine accessories. In contrast, v-belts rarely powered more than two accessories. Instead, older cars with v-belts used to have three or four belts to power the accessories. A serpentine belt does the job of multiple v-belts using only one.

What Does a Serpentine Belt Do?

A serpentine belt turns the water pump, alternator, A/C compressor, power steering pump, and other accessories. The crankshaft pulley drives the serpentine belt which, in turn, makes all the other pulleys turn. The size of each pulley determines how quickly each accessory turns. This is important because alternators, water pump, and power steering pumps need to turn at different speeds while the serpentine belt always turns at the same speed as the engine. The higher the rpm, the quicker the belt rotates.

Serpentine Belt vs Timing Belt

The serpentine belt and the timing belt are not related to one another, but they are both essential for proper engine operation. The easiest way to differentiate a timing belt and a serpentine belt is by looking at their location. Timing belts are located inside the front engine cover and keep the crankshaft and the camshaft in-sync.

On the other hand, the serpentine belt powers accessories, but does not control the timing of the engine. A failing timing chain will not cause the same problems like a faulty serpentine belt. Also, inspecting a serpentine belt is quite easy while inspecting a timing belt requires the removal of many engine components.

Many vehicles built in the 1990s and 2000s power the water pump from the timing chain. The design helps prevent breakdowns because timing belts are more durable and longer-lasting than serpentine belts.

Serpentine Belt Noises and What You Can Do to Fix it

Worn serpentine belts can cause a high-pitch squealing sound. The sound is often most noticeable when the engine starts for the first time of the day. The noise can also happen when accelerating and on downshifts. Unlike v-belts, serpentine belts cannot be tightened to eliminate the noise.

In that case, drivers have two options when a serpentine belt is making noise: spray it with a special lubricant or replace the belt with a new one. Auto parts stores sell spray specifically engineered to cure squealing belts. However, this is only a temporary fix. Most of the time, when a serpentine belt starts to make noise, it is an indication that the belt needs replacement as soon as possible.

If after further inspection, the belt seems fine. You may have a problem with the belt tensioner or one of the pulley's bearings might be seized.

When to Replace a Serpentine Belt and How to Inspect One

Inspecting a serpentine belt is an easy task that takes only a few seconds. It's a good idea to regularly check the belt for signs of wear when checking oil and other fluids. To inspect the serpentine belt, DIYers need to find a section of the belt that can be seen. The belt is located on the front of the engine. Look for shiny spots, cracks, and missing chunks. If any of these signs of wear are evident, it's time to replace the serpentine belt.

Nonetheless, it is good practice to replace the serpentine belt according to the manufacturer's recommended interval. Preventive maintenance like this will reduce the risk of unexpected breakdowns and engine damage a broken belt can cause. Drivers should also inspect the pulleys on the front of the engine. Loose pulleys or worn out pulley bearings can significantly reduce the lifespan of your serpentine belt so make sure they are in good condition when replacing it.

How to Replace a Serpentine Belt

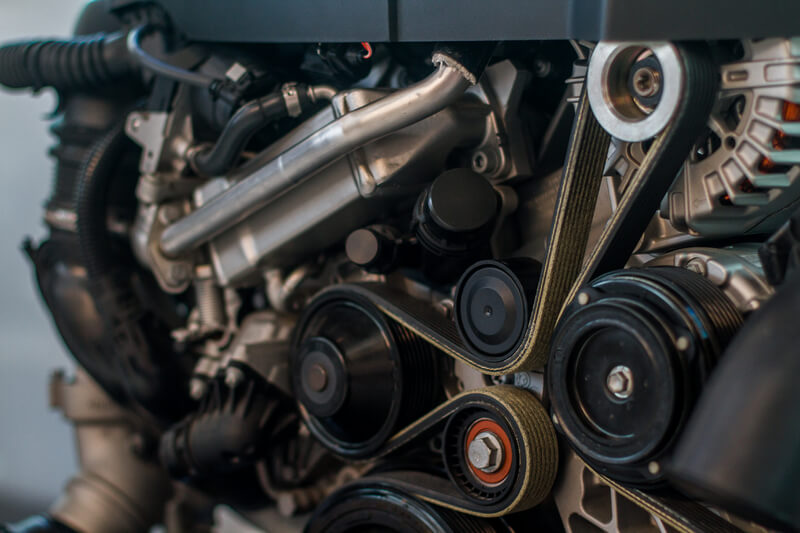

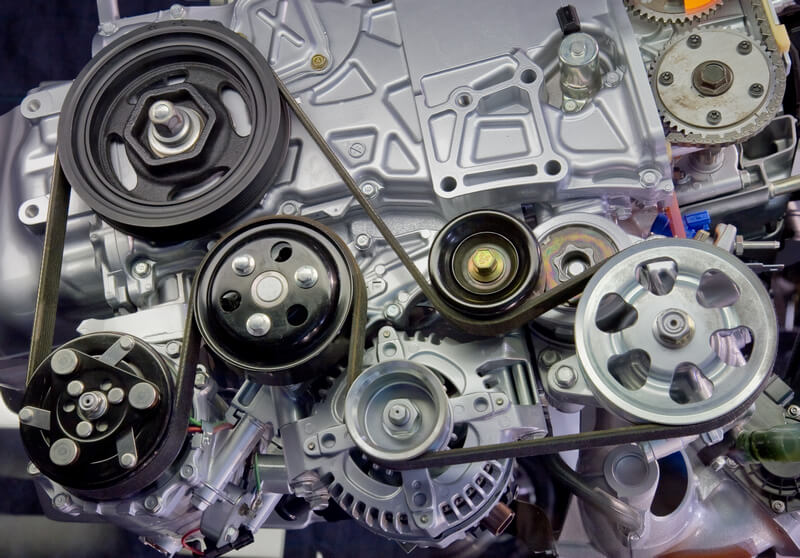

When looking at the serpentine belt, it may seem almost impossible to replace it without taking most of the engine apart. The belt snakes around in and out of various pulleys, looping up and down across the front of the engine. Every engine that uses a serpentine belt has pulleys that do not drive any equipment. These pulleys are called idler pulleys. Their only job is to route the serpentine so it can connect every drive pulleys. One of the idler pulleys will be mounted on a tensioner which job is to keep the correct tension on the belt at all times. The tensioner pulley is the key to removing and replacing a serpentine belt.

The Tensioner Pulley

The Tensioner pulley arm will have a square hole, commonly 3/8", just like a ratchet head. Using a long ratchet, simply rotate the idler pulley arm until the tension on the serpentine belt releases. Then, it's simply a matter of unwinding the belt from the engine pulleys. Always inspect the tensioner pulley once the belt is off. The pulley should turn smoothly and easily. If it drags, makes noise, or can be wiggled on its support, replace the tensioner pulley before re-installing the new serpentine.

Always remember to draw a diagram of the course the serpentine belt takes before removing it. This step makes reassembly much easier. It can be very difficult to remember how a serpentine belt was routed once the belt is in your hands.

With a new belt in hand, all that is necessary is to reinstall the belt, following the same path the old belt uses. It's best to save the tensioner pulley for last, making sure each pulley is in contact with the new belt without twists. Make sure the belt is sitting even on the pulley before letting go of the tensioner pulley and tightening the belt. Once the idler pulley engages, the belt will have the correct amount of tension.

Pro Tip:

Save old belts, even if they have cracks or shiny spots. Keep the old belt in the trunk as a spare in case the new belt breaks. It is not uncommon for various things to cause an engine to "throw" a belt, often destroying the part in the process. A spare, even if it's noisy, will at least give the driver a shot at getting to a repair shop or an auto parts store.

Cost to Replace a Serpentine Belt

Serpentine belts are inexpensive parts. Most owners can find a replacement serpentine belt at an auto parts store for around $30. Also, it takes about 20 minutes to replace one on most cars. The most difficult part of replacing a serpentine belt is figuring out the correct route for the belt to fit. This can be a little bit of a challenge, particularly when the engine threw a belt and you haven't had the time to draw the routing diagram somewhere.

Most repair shops will charge around $100 to replace a serpentine belt. The job takes less than 30 minutes to complete and is often done while the customer waits. By replacing a serpentine belt at home, owners can save as much as $70 over the cost of shop rates.

Where to Find Serpentine Routing Diagrams

A diagram showing how the belt runs is invaluable when installing a new belt. Many cars and trucks will have a decal or sticker on the radiator support or the bottom of the hood showing how to install the belt. Unfortunately, after a couple of years, this label is often illegible or missing due to the high heat and dirty conditions under the hood. If the sticker is missing, you can always find detailed instructions and a routing diagram in your car's repair manual.

Frequently Asked Questions (FAQ)

How do I know when my serpentine belt needs to be replaced?

Look for visible signs of wear, such as cracks, shiny spots, or missing chunks on the belt. Squealing noises, especially during startup or acceleration, can also indicate it's time for a replacement.

How long does a serpentine belt typically last?

Serpentine belts usually last between 60,000 to 100,000 miles, but it’s always best to follow your vehicle’s manufacturer-recommended replacement interval to avoid unexpected failures.

What happens if my serpentine belt breaks while driving?

If your serpentine belt breaks, you'll lose power to critical accessories like the water pump and alternator, which can cause your car to overheat and eventually stall. It’s crucial to replace a worn belt before it breaks.

Can I replace my serpentine belt myself?

Yes! Replacing a serpentine belt is a simple task that most DIYers can handle with basic tools. Just make sure to inspect the tensioner pulley and follow the proper routing diagram.

Can I drive with a squealing serpentine belt?

While it may be possible to drive with a squealing belt, it's not recommended. A squealing belt is a sign that it’s worn and should be replaced soon to avoid a complete failure.

Serpentine Belt Maintenance: The Key to Avoiding Unexpected Breakdowns

The best way to prevent an unexpected breakdown due to a broken serpentine belt is through regular inspection. A quick glance while checking your oil or other fluids can save you from a major headache down the road. If you spot cracks, shiny patches, or hear that telltale squeal, don’t wait—get it replaced. The good news is that replacing a serpentine belt is one of the easier jobs you can tackle at home, using nothing more than common hand tools and a reliable repair manual. It’s a simple DIY task that can save you a lot of money and frustration.

If your serpentine belt does break, especially one that drives the water pump, it’s crucial not to drive the vehicle. Running an engine without a functioning water pump will quickly lead to overheating, which can cause catastrophic damage like blown head gaskets, warped cylinder heads, or even a ruined radiator. In short, it’s not worth the risk.

A little preparation can go a long way. Keeping a spare belt in your trunk—yes, even a worn but intact one—could mean the difference between a quick roadside fix and a costly tow truck ride. While it might not be a permanent solution, having that spare belt on hand could at least get you home or to the nearest repair shop. So, take the time to inspect, replace, and keep a backup handy—you’ll thank yourself when you avoid an unnecessary breakdown and the hefty repair bills that come with it.