Most amateur mechanics start out buying a set of tools for a reasonable, fairly low price. Many of these sets of tools will have the basic sockets and wrenches the do-it-yourself auto repair person needs for most basic jobs, plus a bunch of extra odds and bits that might be useful someday.

These budget-friendly sets are fine for light use and occasional projects but won't hold up to the rigorous use professionals need from their tools. When upgrading from a basic set, the wide variation in the cost of professional tools can be overwhelming. But is it worth the price to buy professional tools? What makes a mechanic’s professional tools better than low-cost tools used by amateur mechanics?

The Professional Difference

Professional mechanics need the best, highest quality, most expensive tools to do the job, right? No professional mechanic would ever use a low-cost tool to work on a customers car, would they?

Doing it by Hand

Pro-quality tools do offer some advantages over low-cost tools for mechanics. One of the most vital tools any mechanic needs to have on a daily basis is a high-quality ratchet. A cheap ratchet will have a sticky, clanky mechanism that is not smooth or easy to use. Low-quality ratchets use low-quality internal components, the little gears that allow the ratchet to function. Over time, these gears wear out and the ratchet either will not engage correctly or the mechanic has to fiddle with the tool constantly. A tool that doesn't work correctly frustrates a mechanic quickly and makes jobs take longer.

For a professional mechanic turning wrenches eight or more hours a day, every day, a cheap ratchet is going to be a source of irritation and frustration that makes jobs take longer -which means less pay for the mechanic. The home mechanic can probably live with a clunky, cheap ratchet, but upgrading to a pro-quality tool will reduce frustration.

Snap-On Tools are regarded by professionals as among the best tools a mechanic can own. Snap-On tools are known for Mt. Everest-sized prices. Consider that a complete Craftsman tool set that features two sizes of ratchet plus standard and metric sockets for both ratchets runs around the same cost as a single ratchet and socket set from Snap-On.

Most mechanics that have tools from Snap-On, MAC, or one of the major manufacturers will have spent more than $50,000 just on tools.

Brace for Impact

Home mechanics frequently tackle automotive repair projects in the driveway using hand tools. Most sockets won't break when a mechanic uses them correctly. But, when the home mechanic upgrades to using air-powered tools, a standard socket will not hold up to the stress and can be dangerous to use.

Impact sockets are made of special alloy metal and are designed to handle a ton of abuse. When trying to remove old, grubby, rusty car parts, an air impact ratchet can be the difference between getting the job done and spending hours beating a bolt out by hand.

Impact sockets are substantially more expensive than a standard socket set. Frequently, buyers will need to get several sets to get all the sockets needed for air impact use. The expense is worth it when tearing down a suspension system quickly and easily. Avoid no-name sockets for impact use. This is one tool the average mechanic should not be cheap about buying. Impact sockets that shatter under use can throw shards of metal in unpredictable directions. A high-quality impact socket will stand up to years of abuse. After spending a bunch of money on an air compressor, hoses, and an impact ratchet, saving money on sockets is the wrong thing to do.

There are plenty of low-cost automotive tools mechanics use every day that do not come from MAC or Snap-On, or even Craftsman. The do-it-yourself home mechanic can save money buying individual tools, such as 3/8” and 1/2” ratchets from Snap-On or MAC, and getting other tools that are less expensive from other sellers.

Saving Money For Pro Results

Likely the most expensive drawer in a professional mechanic’s toolbox, the wrench drawer can be worth more than the cars the tools are fixing. Pro-quality wrenches are nice to use -smooth, well-designed shafts, perfect sizes and durable beyond belief. Low-quality wrenches may have a certain amount of variance between the intended size and what the tool ended up with. In many situations, this minute difference may make little or no difference.

When working on a customers car, though, and a wrench slips off a nut because the tool is slightly off or worn out, the mechanic can get into a serious issue. Stripped, broken bolts and nuts take time and effort to remove and repair, and often, a mechanic will not get paid for the damage they do to a customers car.

Before running off to the Snap-On truck, though, consider what use wrenches really are for projects. An inexpensive set from Craftsman or Husky will hold up very well over time and have high-quality protections. Avoid obviously cheap tools that are not made of some type of alloy.

Out of the Tool Box

Diagnostic tools are used by a mechanic to know why a car is not performing correctly. The do-it-yourselfer can save a chunk of money buying good quality, lower-cost diagnostic tools rather than the professional versions that require financing.

Almost every car and truck built since the early 1980s have some form of computer that performs various functions. OBD-II is a common standard in most cars. This computerized system is responsible for logging and reporting inconsistent results from various engine sensors and is primarily intended as an emissions control. An OBD-II code reader will show the engine codes for problems.

OBD II scanners from the big brands are prohibitively expensive. Lower-cost units work just as well, though may not have some of the more intricate features of a professional quality code scanner. The home mechanic can use a low-cost OBD-II scanner.

Shop around and compare features on scanners.

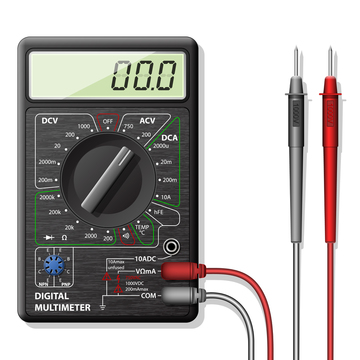

A multimeter is one of the most commonly used diagnostic tools in a professional shop. A good quality multimeter will have an easy to read scale and will be accurate. A multimeter finds voltage, amperage, and resistance on electrical circuits. Some multimeters have features for checking RPMs, dwell, and many other features. An inexpensive multimeter will often work just as well as a more expensive model for much less money.

On the Bench

Automotive engineers machine parts. Some of the tools commonly used by automotive engineers are presses, grinders, and other metal-working tools.

How Much Can You Press?

Mechanics install press-to-fit parts and bushings on a bench press. A bench press is essentially a strong bottle jack on a stand that ensures the parts remain parallel while placing huge amounts of pressure to fit the parts together easily. Automotive engineers use a press with a drill bit to machine perfectly aligned holes.

Clamp it Up, Grind it Down

A bench vice is a mechanics best friend. An adjustable vice is like a person having an extra pair of the strongest hands known to man. No vice is really “cheap.” A vice needs to be robust and intended to take a beating. A cheap vice made in countries that tend to allow unregulated metallurgy is likely to break. A broken vice can allow parts under pressure to explode everywhere, and worse, can fall on the operators' feet, breaking bones.

Professional-quality vices can run several hundred dollars, while lower-cost units might be a quarter the cost or less. Forged components are tougher than cast parts.

Bench grinders are amazing tools for cleaning parts up and grinding down metal. A less expensive bench grinder will work just fine for the average home mechanic. Professionals that are going to be running the grinder for hours a day, day after day, should seriously consider a top-quality grinder.

More important than a high-quality grinder is high-quality components. Use good grinding stones and wire wheels. Invest in high-quality eyewear and gloves, particularly if using stainless steel wire wheels. The wire strands come free from the wheel during use and a stainless steel wire embedded in an eyeball is no fun. An eye surgeon will have to use tweezers to remove stainless steel since it is not magnetic.

Get it Up

Working on a car on the ground can be difficult, and often will prevent the home mechanic from completing many jobs. Professional quality jacks and jack stands are nice to have but are not essential for the home mechanic. Make sure the hydraulic jack can handle the weight of the vehicle and use good quality steel jack stands. Do not save money on jack stands. A collapsed jack stand while under a car is one of the single most terrifying experiences a person can be lucky enough to live through.

A portable car lift is a great tool to have and is the best way to safely lift a car. Avoid the cheapest thing on the market. This is one area the do-it-yourselfer really needs to spend good money. A good quality jack and stands is not a huge expense, but a portable car lift might be outside the price range for most home mechanics.

Buying Used

The internet has allowed access to pre-owned tools unlike anything in history. Tools like air impact guns, ratchets, and toolboxes can be a great value to the home mechanic. Avoid tool sets that are rusty or show obvious signs of abuse.

Used diagnostic equipment is available for the home mechanic to buy. Check used tools carefully before buying. Don't buy broken tools.

Used tools are available for less money than new tools, but buyers should inspect used tools carefully for wear and damage. Ratchets are rebuildable, though, so don’t be to put off by a Snap-On ratchet that is a little clunky feeling if the price is right.

Putting it All Away

Some mechanics have more square footage in their toolboxes than in their homes. A top quality toolbox can be more than a year's earnings from one of the pro companies.

The home mechanic can save a ton of money by making some sacrifices when it comes to toolboxes. Smaller drawer sets are cheaper, as are boxes that do not feature high-quality ball bearing drawers. Shop around and determine needs. Many home mechanics are better off with a smaller toolbox that holds essential tools and is moveable rather than an apartment-sized tower of cabinets. Toolboxes are a great thing to search for used.

Professional quality tools can be really nice to use but often are not significantly better than lower cost tools available to the average consumer. Shop carefully for the particular tools needed when upgrading from a toolset kit to a more professional-style tool assortment for years of productive use and safety.