Harvest season is the busiest time of year, and your combine harvester is the key to getting the job done. It gathers, threshes, and cleans your crops—so keeping it in top shape is crucial to avoid costly downtime.

Whether you’re new to farming or have been at it for years, maintaining your combine properly can make all the difference. In this guide, we’ll walk through five key maintenance steps to keep your machine running smoothly when it matters most. These straightforward yet thorough checks will help you avoid costly breakdowns, improve efficiency, and keep your harvest on track.

By the end, you'll have the know-how to get your combine field-ready so you can focus on what really matters—getting the most out of your harvest.

Step 1 — Engine and Cooling System Maintenance: The Heart of the Combine

The engine is the backbone of your combine. It powers everything, from moving through the field to running the mechanisms that harvest your crops. Keeping both the engine and cooling system in good shape is crucial to prevent overheating, poor fuel use, or even a complete breakdown during harvest—a situation nobody wants to deal with when time is tight.

Here’s what to keep an eye on to make sure your combine’s engine and cooling system stay reliable:

Change the Engine Oil and Filter Regularly

Frequency: Every 100-200 hours of operation (or as specified by the manufacturer)

Engine oil is what keeps the moving parts inside the engine from wearing out. Over time, oil gets dirty from dust and debris, making it less effective. You should change the oil and oil filter regularly—usually after every 100-200 hours of operation, but check your manual for specifics.

Check the Coolant Level and Top Off as Needed

Frequency: Daily during harvest season

Coolant keeps your engine from overheating. Before harvest kicks off, make sure the coolant is topped up to the right level. Once the season starts, check it daily—running low can cause serious, costly damage to your engine.

Inspect and Clean the Radiators

Frequency: Every few days or as needed

Your combine runs in dusty conditions, and that dust can clog the radiators. When that happens, the cooling system struggles to keep the engine from overheating. Use compressed air to blow out the radiator every few days. If the dirt buildup is heavy, give it a thorough wash.

Check and Clean the Air Filters

Frequency: Daily during harvest season

Air filters can clog up fast during harvest, cutting off the engine’s airflow. Check them every day, and replace them if they’re packed with dust. Clean air filters will help your engine run more efficiently and last longer.

Step 2 — Inspecting and Replacing Belts, Chains, and Bearings

The belts, chains, and bearings on your combine do a lot of the heavy lifting during harvest. They’re responsible for transferring the engine’s power to all the moving parts, from the cutting blades to the augers. If any of these components wear out or fail, it could mean serious downtime—something you definitely want to avoid when the harvest is in full swing.

Belt Maintenance

Frequency: At least once a season; daily visual checks during harvest

Belts transfer power to different parts of the machine, but over time, they can crack, fray, or lose tension. During the season, make a habit of inspecting the belts for visible damage. Cracks and fraying mean a belt is close to failing—don’t wait for it to snap and slow you down. Keep an eye on tension, too—belts that are too loose will slip, while those that are too tight will wear out faster. And don’t forget to check alignment. If a belt is misaligned with the pulleys, it’s going to wear unevenly and cause you problems sooner than later.

Even if they look fine, it’s a good idea to inspect your belts at least once a season and always have a few spares on hand—you’ll thank yourself when one gives out at the worst possible time.

Chain Maintenance

Frequency: At least once a season; regular checks during harvest

Chains are just as crucial, powering components like augers and conveyors. Over time, chains stretch, and when they do, they lose efficiency and become prone to breaking. A good way to check is by measuring the chain—if it’s stretched more than 3% beyond its original length, it’s time for a replacement. You’ll also want to look for worn links and sprockets. Sprockets with worn or cupped teeth can cause the chain to slip, which is something you don’t want to deal with in the middle of harvest.

Keeping the chains lubricated is equally important. A well-lubed chain will last longer and perform better. Whenever you replace a chain, it’s smart to replace the sprockets at the same time—worn sprockets can cause a new chain to wear out quickly.

Bearing Maintenance

Frequency: Before each season; daily checks during harvest

Bearings might not seem as flashy as belts or chains, but they’re just as important. They reduce friction and keep everything moving smoothly. The trouble is, bearings can wear out, rust, or even seize up, which can lead to bigger problems if left unchecked.

When inspecting bearings, feel for any excessive play in the components they support. If things feel loose, the bearing might be worn out and need replacing. Pay attention to any strange noises, like grinding or squealing—those are usually signs that a bearing is in bad shape. Excessive heat is another red flag. If a bearing is running hot, it’s likely on its way to failure. And, of course, if you notice any rust or corrosion, it’s best to replace the bearing immediately.

Keeping bearings well-lubricated is one of the simplest ways to extend their lifespan. Before each season, lubricate them thoroughly and replace any that seem rough or worn. It’s always better to swap out a worn bearing early than to deal with the fallout of one failing during harvest.

Step 3 — Maintaining the Threshing and Separating Systems for Maximum Efficiency

The threshing and separating systems are the heart of your combine’s function. These systems separate the valuable grain from the chaff and other materials, so if they’re not in top shape, you risk losing or damaging your crop. Regular maintenance will keep these systems running efficiently, helping you get the most out of your harvest.

Threshing System

Frequency: Before each harvest and as needed

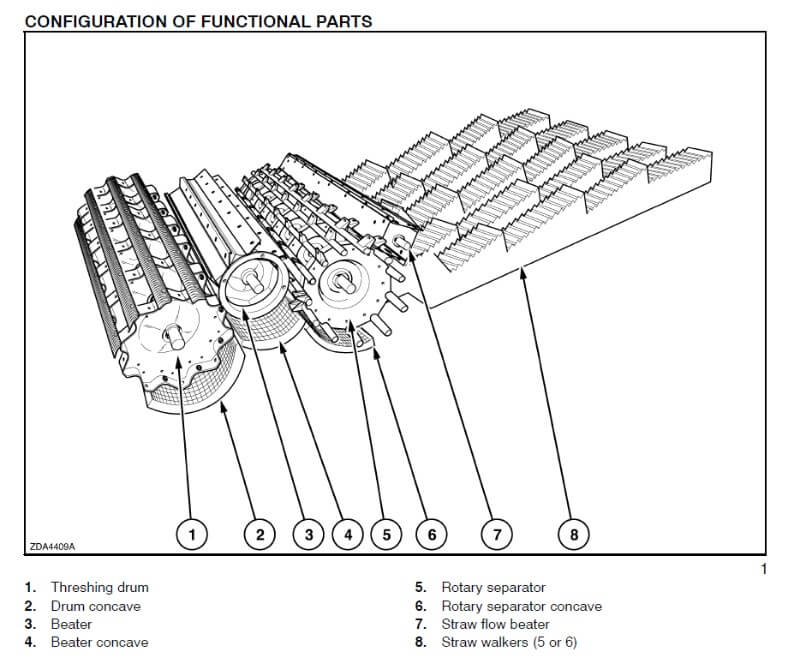

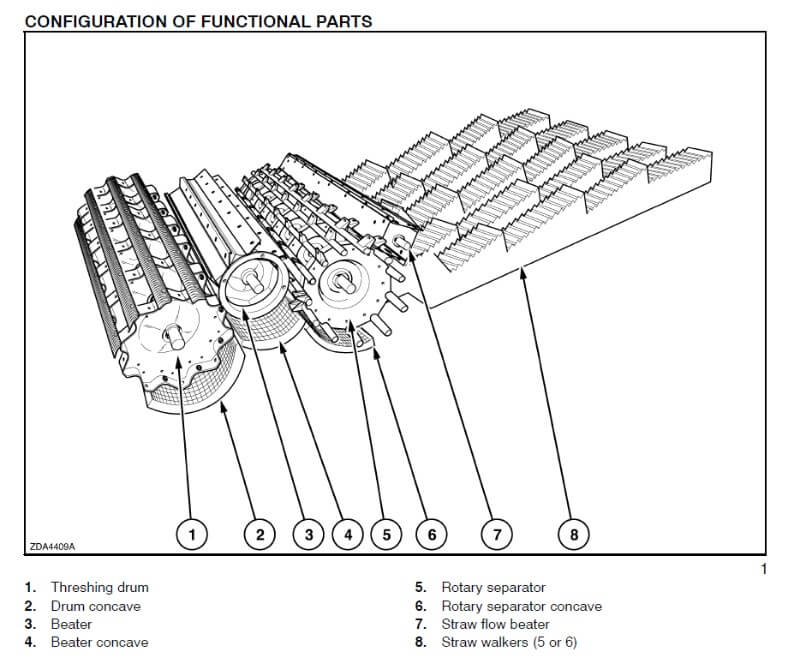

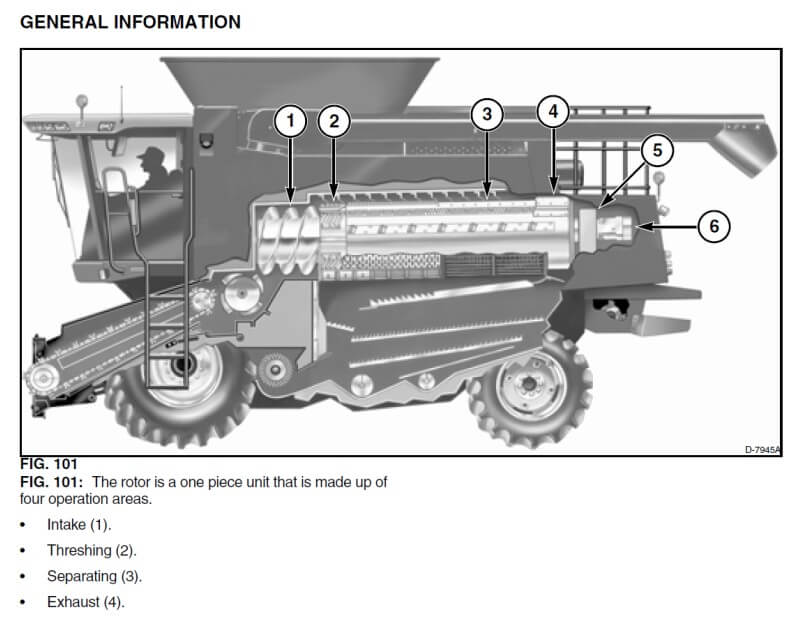

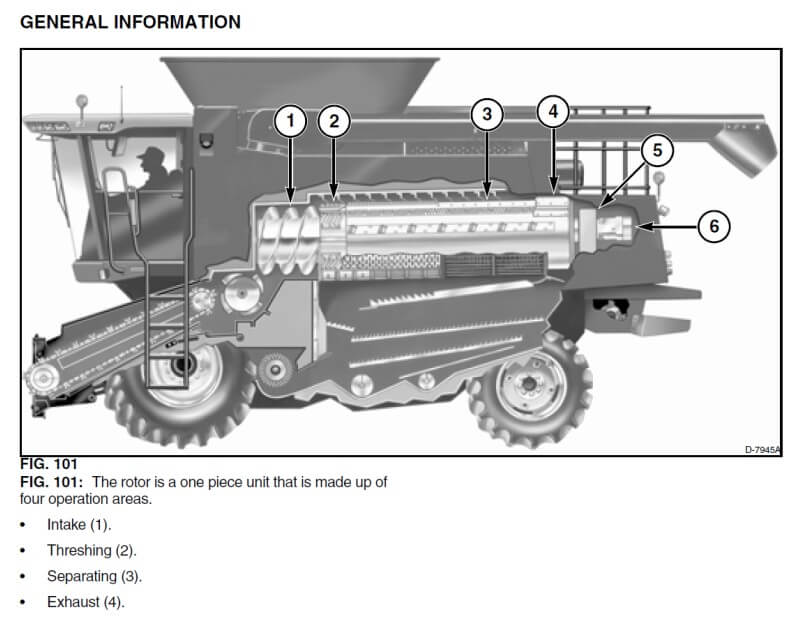

The threshing system mechanically separates grain from the plant. Components like the cylinder, rotor, and concaves are crucial to its function. Here’s what you need to check:

- Inspect Concaves for Wear or Damage: Concaves help separate the grain, but they wear down over time. Check them before each harvest for wear or bending. Replace concaves that are worn or warped, and make sure the concave gap is properly adjusted for each crop to avoid incomplete threshing or grain damage.

- Check and Adjust Cylinder or Rotor Speed: The cylinder or rotor must run at the right speed for the crop you’re harvesting. Too fast, and you’ll damage the grain; too slow, and it won’t separate properly. Check your operator’s manual for the recommended speed and adjust it before starting.

- Replace Worn Rasp Bars and Separating Grates: Rasp bars help separate grain by striking or rubbing it off the plant. Worn bars make this less efficient. Similarly, separating grates can become damaged or clogged. Inspect and clean both regularly, and replace them if needed.

Separating System

Frequency: Before each harvest and periodically during the season

Once threshing is done, the separating system ensures the remaining grain is separated from the plant material. This is where straw walkers or rotors come into play. Keep them working properly with these checks:

- Check for Proper Straw Walker Function: Straw walkers gently shake the remaining plant material to let the grain fall through. Inspect them for cracks or blockages, and make sure they’re clear of debris before harvest.

- Inspect Rotor and Tine Condition: In rotary combines, the rotor and tines tumble the plant material to release the last bits of grain. Look for worn or bent tines, and replace them before the harvest season starts. Clean the area to avoid blockages.

- Adjust Concave and Rotor Settings for Different Crops: Each crop requires different settings for the concave and rotor. Adjust the spacing and speed based on the type of crop you’re harvesting to avoid grain loss. Check your operator’s manual for the right settings for each crop.

Step 4 — Optimizing Grain and Residue Handling Components

After threshing and separating, your combine’s job isn’t done yet. It still needs to move the grain to storage and spread the leftover material evenly across the field. Both systems—the grain handling system and the residue handling system—need to be in good condition to prevent grain damage and ensure proper residue distribution for soil health.

Grain Handling

Frequency: Before the season starts and regular inspection during harvest

Grain handling components, like augers and elevators, move the grain through the combine and into the storage tank. Rough handling here can lead to cracked or broken grain, which reduces its market value. Here’s how to keep things running smoothly:

- Inspect Augers for Wear or Damage: Augers are the screw-like components that move the grain. Over time, the edges can get sharp, bent, or worn down, leading to grain damage. Check them before harvest, and replace any augers that are damaged or too sharp.

- Check Elevator Chains for Tension and Wear: Elevator chains move the grain vertically. Loose chains can slip, while tight chains cause excessive wear. Make sure they’re properly tensioned, and replace any that have stretched over 3% of their original length. Also, check the paddles—if they’re damaged, replace them to keep the grain moving evenly.

- Monitor the Grain Tank and Unloading System: The unloading augers move grain from the tank to your trailer. Damaged or clogged augers can cause delays and spills. Inspect and clean the unloading system regularly to keep things flowing smoothly.

Residue Handling

Frequency: Before each harvest and monitored regularly

The residue handling system chops and spreads leftover material like straw and chaff back onto the field. Properly spread residue helps improve soil health for the next season. Here’s how to keep the system in top shape:

- Ensure Proper Function of Straw Choppers and Spreaders: Choppers cut up the plant material while spreaders distribute it across the field. Dull or unbalanced blades can cause uneven residue spread. Check the blades for sharpness and balance, and replace them if necessary. Also, ensure the spreader paddles are properly adjusted for even coverage.

- Inspect and Adjust Spreader Speed and Vanes: The speed of the spreader and the position of the vanes affect how evenly the residue is spread. Adjust these based on the crop and the amount of residue, following your operator’s manual for the correct settings.

- Monitor for Blockages or Build-Up: Residue build-up can cause blockages in the system. Clean out any debris regularly, especially when harvesting crops that leave behind a lot of material, like corn or wheat. Clear any blockages as soon as you notice them.

Step 5 — Tire and Track Maintenance: Keeping Your Combine Moving

Tires and tracks might not get as much attention as other systems, but they’re just as crucial for keeping your combine moving through the field without hiccups. A fully loaded combine can weigh over 20,000 pounds, and all that weight rests on your tires or tracks. So, making sure they’re in good shape is essential to avoid slip, uneven performance, or soil damage. Let’s dive into what you need to know.

Tire Maintenance

Frequency: Weekly during harvest (or more frequently if terrain conditions change)

Tires are the more common choice for most combines. The secret to keeping them working at their best? Regular attention to pressure, wear, and balance.

You know how hard it is to get through soft or wet fields with underinflated tires—they create more resistance, burn fuel faster, and make your combine sluggish. On the flip side, too much air and you risk compacting the soil, which can cause long-term damage to your land.

So what should you do? Check your tire pressure once a week during the harvest or more often if the terrain changes. Use a good tire pressure gauge and adjust it according to the manufacturer’s guidelines. It’s quick, easy, and keeps your tires working efficiently.

Then there’s the wear and tear. Your tires are going to face tough conditions—rocks, stubble, uneven ground. Keep an eye out for cracks, bulges, or worn treads. Catching these issues early can save you a blowout in the middle of the field. If you spot any serious damage, it’s time to swap the tire out before you’re stuck waiting for repairs.

Finally, don’t forget about alignment and balance. If your tires are wearing unevenly or you feel vibrations while you drive, you’ve got a problem. Get them checked and corrected to avoid bigger issues down the road.

Track Maintenance

Frequency: Before the season starts and monitored throughout the harvest

If your combine runs on tracks, especially in wet or soft soil, maintaining them becomes even more important. Tracks spread the weight more evenly, but they also need more attention to stay in top shape.

First up—tension. Too loose? The tracks might slip or come off. Too tight? You’ll wear them out quickly and put a strain on the undercarriage. Before the harvest season kicks off, check and adjust the tension following your combine’s manual.

Now, tracks take a lot of abuse from rocks and debris. Over time, the tread wears down, reducing traction. Check the tracks for signs of wear and inspect the undercarriage for damage, especially around the rollers and idlers that keep everything aligned.

Here’s a tip: if your rollers or idlers are worn out, replace them right away. Don’t wait for them to fail mid-harvest. A smooth-running track system is crucial for navigating tough fields without losing traction or damaging the soil.

Frequently Asked Questions (FAQs)

How often should I perform maintenance on my combine harvester?

Regular maintenance should be done year-round, but a thorough inspection is especially important before harvest season starts. During harvest, make sure to check key components—like oil levels, air filters, and tire pressure—daily. Always follow the manufacturer’s maintenance schedule for servicing the major systems to avoid breakdowns during the busy season.

What are the most common issues that lead to breakdowns during harvest?

The most common issues include engine overheating, belt or chain failures, clogged air filters, worn concaves or rasp bars, and poor tire or track condition. Regular inspections and maintenance can prevent most of these problems, especially if worn belts or chains are caught early.

How do I know when to replace the belts and chains on my combine?

Replace belts if you notice cracks, fraying, or glazing. Chains should be replaced if they’ve stretched by more than 3% of their original length. It’s also a good idea to replace sprockets when you replace chains since worn sprockets can wear down new chains faster.

What’s the best way to prevent soil compaction caused by my combine?

Keeping your tires properly inflated and maintaining your tracks is key to preventing soil compaction. Underinflated tires or worn tracks can cause uneven weight distribution, compacting the soil and affecting future crops. In wet or soft soil conditions, tracks can be better than tires, since they spread the combine’s weight over a larger area.

How can I tell if my combine’s threshing system is damaging the grain?

If you see cracked or broken kernels in the grain tank, the threshing system might be set too aggressively. Check the cylinder or rotor speed and the concave settings—running them too tight or too fast can damage the grain. To reduce damage, regularly check the grain quality and adjust the settings based on the crop you’re harvesting.

Get Your Combine Harvest-Ready with Proper Maintenance

A well-maintained combine is key to a successful harvest season and a valuable long-term investment. Staying on top of maintenance may take time, but it’s time well spent to avoid costly breakdowns and ensure that your harvest goes off without a hitch. Every check, every part replaced, and every adjustment you make today pays off when your machine runs smoothly, your crops are harvested efficiently, and your bottom line is protected.

When the fields are ready, your combine should be too. Give it the attention it needs now, and it will reward you when it matters most.