Fuel injectors might not get all the glory, but they play a crucial role when it comes to making your engine run smoothly. These small but powerful components work behind the scenes, delivering the perfect mix of fuel and air to keep your car performing at its best while sipping fuel as efficiently as possible.

Why should fuel injectors be on your radar? Knowing how they work can help you take better care of your car and appreciate the technology under the hood. Plus, once you get familiar with them, you'll have a clearer picture of how cars have evolved into the machines they are today.

To help you with that, we’ll break down everything you need to know about fuel injectors—from their early days to the high-tech systems in today’s engines. We’ll also dive into their benefits, common issues, and even what role they’ll play as we shift toward an electric future.

Whether you’re just starting to get into cars or you’ve been wrenching for years, this guide will give you the lowdown on fuel injectors and why they’re such a crucial part of your vehicle. Ready to dive in? Let’s go.

What is a Fuel Injector?

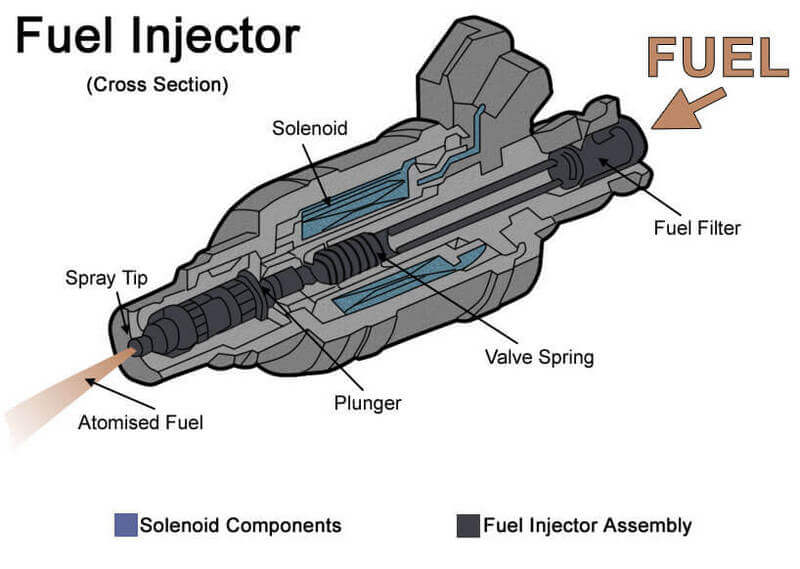

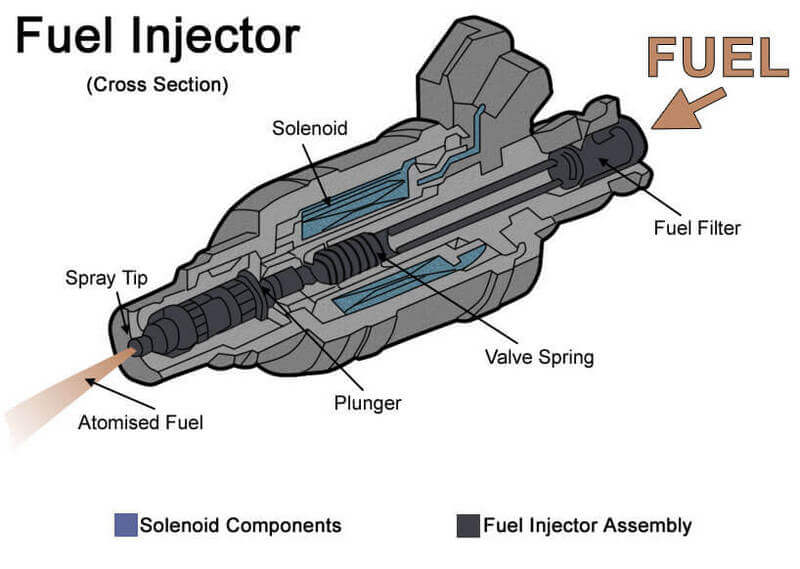

A fuel injector is a crucial part of modern engines, delivering fuel with precision. Its job is to spray fuel into the intake manifold or directly into the combustion chamber, making sure the engine gets the perfect mix of fuel and air for efficient combustion.

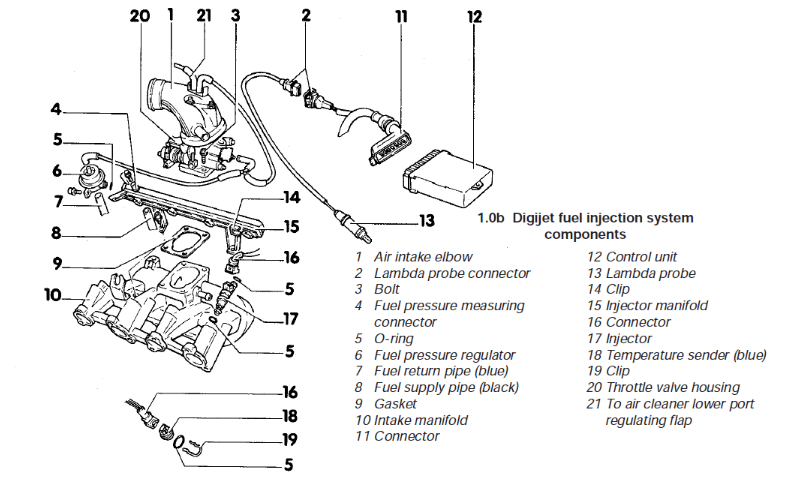

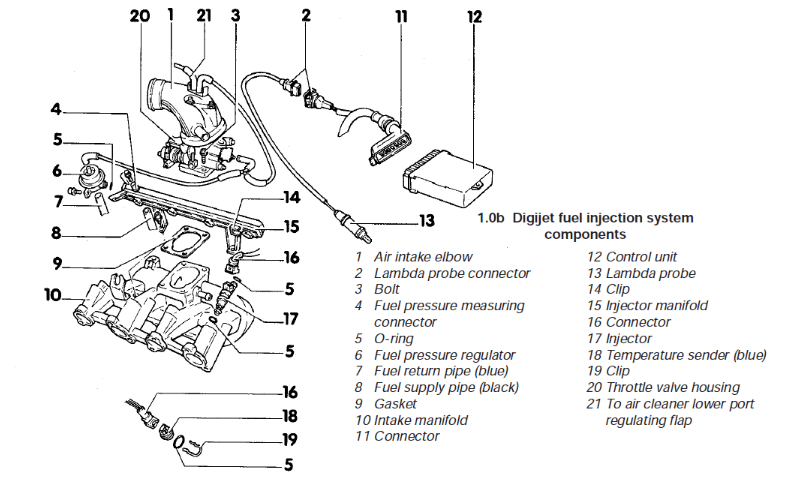

A typical fuel injector system includes:

- Fuel Pump: Sends fuel from the tank to the injectors

- Fuel Pressure Regulator: Maintains consistent fuel pressure in the system, ensuring the injectors receive the right amount of fuel.

- Fuel Rail: A metal bar that distributes fuel evenly to each injector.

- Injectors: Spray fuel into the engine, turning it into a fine mist for optimal combustion.

- Electronic Control Unit (ECU): The brain of the system, controlling when and how long each injector opens by processing data from engine sensors.

- Sensors: Various sensors (like oxygen, throttle position, and airflow) provide real-time data to the ECU, helping it adjust fuel delivery for peak engine performance.

Fuel injectors work like high-pressure nozzles, turning liquid fuel into a mist that mixes with air. This precise mist allows the fuel to burn more completely, improving engine efficiency, performance, and reducing harmful emissions.

Evolution of Fuel Injection Systems

Fuel injection technology has come a long way, evolving from basic mechanical setups to the advanced electronic systems we rely on today. This progress has been driven by the push for better fuel efficiency, reduced emissions, and enhanced engine performance.

Early Days

Fuel injection wasn’t always a staple of automotive engines—it actually got its start in aviation in the early 20th century. Planes needed stable engine performance at different altitudes and orientations, and fuel injection helped make that possible.

The first cars with fuel injection came along in the late 1930s, mainly in diesel engines. Since diesel engines need precise fuel delivery for high compression, fuel injection was a natural fit. But for gasoline engines, carburetors were still the norm due to their simplicity and reliability, keeping fuel injection in the background for a while.

Re-Emergence in the 1980s

Fuel injection made a big comeback in the 1980s. With tighter emissions regulations and the need for improved fuel economy, carmakers started to focus on fuel injection again.

In the beginning, these systems were mechanical, relying on linkages and pressure to control fuel delivery. Known as mechanical fuel injection (MFI), these setups were complex and nowhere near as responsive as today’s systems.

The game changed with the introduction of electronic control units (ECUs). ECUs allowed for precise, real-time adjustments, using data from various sensors to tweak fuel delivery on the fly. This shift to electronic fuel injection (EFI) systems meant better performance, more efficiency, and the ability to meet stricter emissions standards.

Today’s Fuel Injection Systems

Modern fuel injection systems are more advanced than ever before. Direct injection, where fuel is sprayed directly into the combustion chamber, has become the norm in many vehicles. This method allows for finer atomization of the fuel, resulting in more efficient combustion, better power output, and reduced emissions. On top of that, improvements in materials and manufacturing have made today’s fuel injectors more durable and reliable than their predecessors.

How Fuel Injectors Work

Fuel injectors are essentially valves that spray fuel into the engine as a fine mist. This mist then mixes with air to form the perfect fuel-air blend for combustion. The real magic happens in the precise timing and duration of the spray. Deliver too much or too little fuel, and your engine's efficiency, power, and emissions could all take a hit. That’s why modern injectors are finely tuned to deliver just the right amount of fuel at exactly the right moment.

Fuel Delivery Process Explained

- Fuel Pump: It starts with the fuel pump, usually located in the fuel tank. This pump pressurizes the fuel system, sending fuel through the fuel lines to the injectors. The fuel pump ensures there’s a steady supply of fuel, delivered at the right pressure.

- Fuel Pressure Regulator: The fuel pressure regulator plays a crucial role in maintaining the correct pressure within the fuel rail. It adjusts based on the engine’s demand to ensure optimal fuel delivery. A malfunctioning regulator can cause fuel pressure issues, leading to poor performance or even engine stalling.

- Fuel Rail: The fuel moves into the fuel rail, which acts as a distribution center. It holds and distributes fuel evenly to each injector, ensuring that each one gets the right amount of fuel under consistent pressure. This rail is designed to avoid pressure fluctuations that could disrupt fuel flow.

- Powertrain Control Module (PCM): The PCM monitors various inputs like throttle position, engine load, and air-fuel ratio. It uses this data to control when and how long the fuel injectors should open, ensuring the engine gets the precise amount of fuel it needs in any condition.

- Injectors in Action: The PCM sends an electrical signal to the fuel injectors, causing them to open their valves and spray fuel into the intake manifold or directly into the combustion chamber. The fuel is atomized into a fine mist, which mixes with air to form the ideal mixture for combustion. This process is crucial for achieving efficient fuel burn, maximizing power, and minimizing emissions.

- Fuel Return Line (if applicable): In return-style fuel systems, any excess fuel that isn’t used by the injectors is sent back to the fuel tank through a return line, maintaining pressure within the system and preventing over-pressurization.

Role of Sensors and Electronic Control Units (ECUs) in EFI

Think of the electronic control unit (ECU) as the mastermind behind your car’s fuel injection system. It’s constantly taking in data from different sensors to make sure your engine gets the right amount of fuel at just the right time. Here are some of the key players it relies on:

- Mass Air Flow (MAF) Sensor: Measures how much air is coming into the engine, helping the ECU figure out how much fuel is needed for the perfect air-fuel mixture.

- Oxygen (O2) Sensor: Monitors the oxygen levels in your exhaust. If there’s too much or too little, the ECU tweaks the fuel mix to keep everything running smoothly and efficiently.

- Throttle Position Sensor: Keeps track of how much you’re pressing on the gas pedal, so the ECU knows when to ramp up fuel delivery or ease off.

- Engine Temperature Sensor: Tells the ECU whether the engine is cold or hot, helping adjust the fuel mixture accordingly—more fuel when it’s cold, less when it’s warm.

All this data gets crunched by the ECU, which then sends precise instructions to the fuel injectors. It’s this real-time control that helps your engine perform its best, no matter what kind of driving conditions you’re dealing with.

Open-Loop vs. Closed-Loop Systems: What’s the Difference?

Fuel injection systems can work in two different modes: open-loop or closed-loop, depending on what’s happening with your engine.

Open-Loop System

In an open-loop system, the ECU is essentially flying blind—it's using pre-programmed settings to deliver fuel without getting any feedback from the oxygen sensors. You’ll usually see this mode kick in when the engine is warming up, starting, or during heavy acceleration. While it gets the job done, it’s not the most efficient option and tends to produce more emissions because the fuel mix isn't being constantly adjusted.

Closed-Loop System

Closed-loop, on the other hand, is where the magic happens. In this mode, the ECU is in constant communication with the O2 sensors, adjusting the fuel delivery on the fly based on real-time feedback. It’s what your engine uses for everyday driving, and it’s way more efficient. By fine-tuning the air-fuel mix constantly, closed-loop systems not only help boost fuel efficiency but also cut down on emissions and make sure your engine is performing at its best.

Different Types of Fuel Injection Systems

As engines have become more advanced, fuel injection systems have evolved right alongside them. Over the years, various types of fuel injection systems have emerged, each with its own pros, cons, and ways of getting fuel where it needs to go. Let’s break down the main ones: single-point injection, multi-point injection, and direct injection.

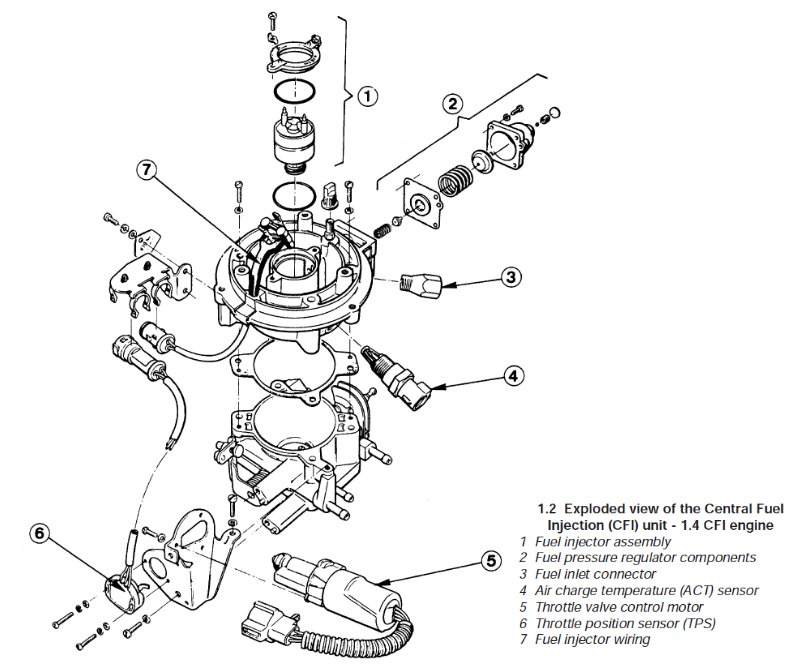

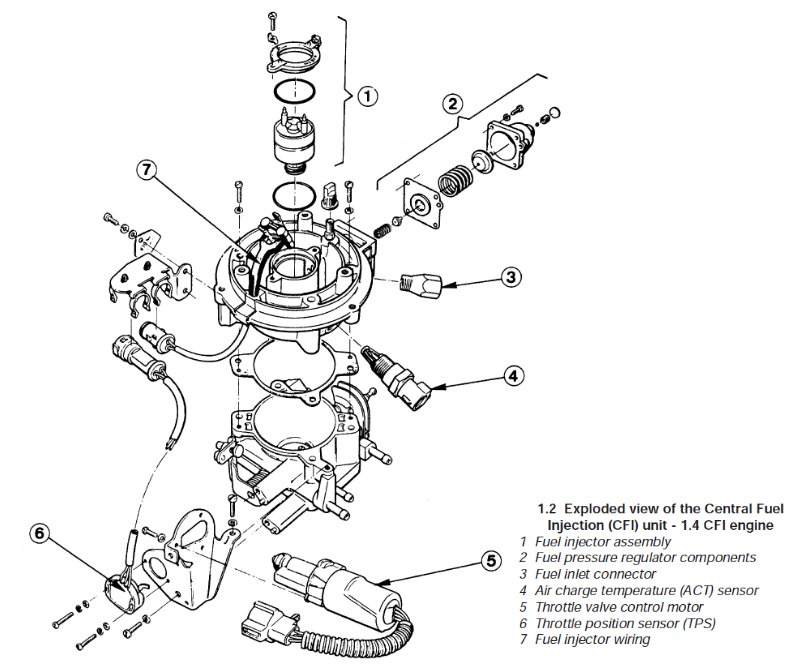

Single-Point Injection (Throttle-Body Injection)

Throttle-body injection (TBI) was one of the first systems to step in and replace carburetors, helping engines run more efficiently. Instead of multiple injectors, this setup uses just one (or sometimes two) injectors positioned in the throttle body above the intake manifold.

How It Works:

- The injector sprays fuel into the intake manifold, where it mixes with the incoming air.

- This air-fuel blend is then distributed evenly to all the engine's cylinders through the intake valves.

| Advantages | Disadvantages |

|---|---|

| Simpler design, making it cheaper to produce compared to more advanced systems. | Fuel delivery isn't as precise, which can hurt fuel efficiency and increase emissions. |

| Easy to install on older engines that were built with carburetors in mind. | If the injector fails, it impacts the entire engine since there’s only one point of fuel delivery. |

Multi-Point Injection (Port Injection)

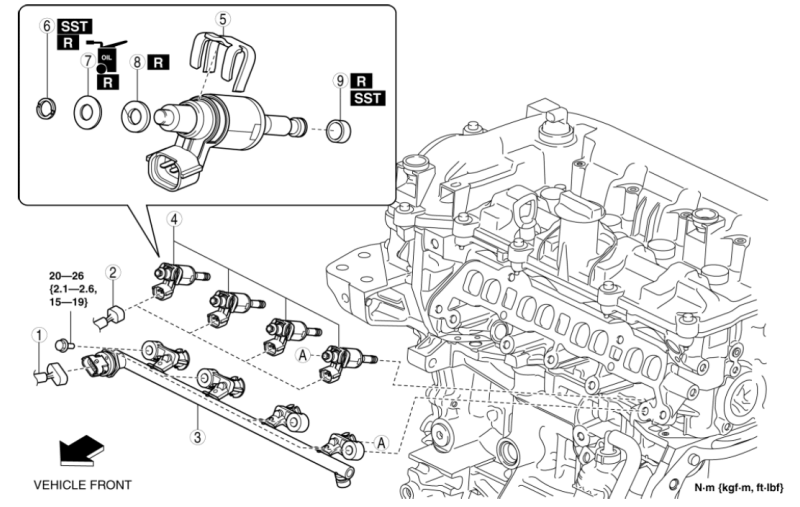

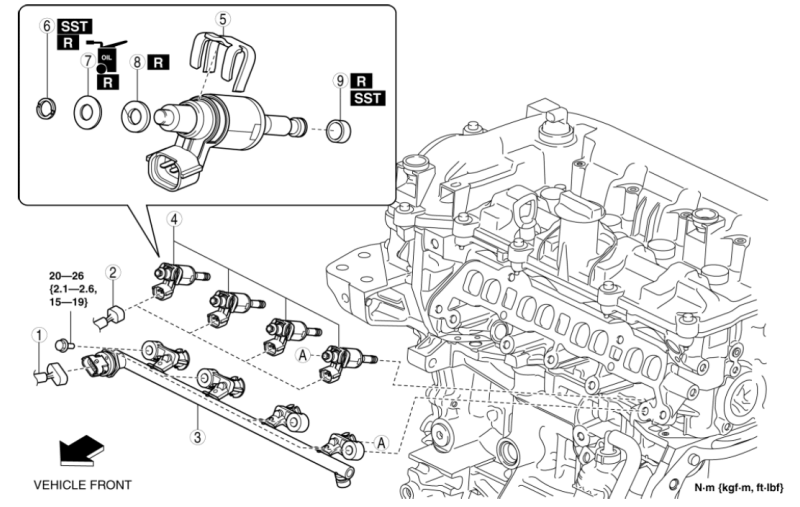

Multi-point injection, or port injection, takes a step up from single-point systems by using separate injectors for each cylinder. These injectors are positioned near the intake valves, allowing for much more accurate fuel delivery compared to older methods.

How It Works:

- Each injector sprays fuel into the intake port just ahead of the intake valves.

- The fuel and air mix in the intake port, and when the intake valve opens, this mixture flows into the combustion chamber.

Types of Multi-Point Injection:

- Simultaneous Injection: In this type, all injectors fire at the same time, regardless of when the intake valves are actually open. It’s simpler, but not as efficient because the fuel waits around until the valve opens.

- Batched Injection: Here, injectors fire in groups, timed according to the engine’s firing order. It’s a step up from simultaneous injection because it’s more synchronized with the engine’s operation.

- Sequential Injection: This is the most advanced of the three. Each injector fires individually, precisely timed with the opening of its intake valve, which leads to better fuel efficiency and engine performance.

| Advantages | Disadvantages |

|---|---|

| More accurate fuel delivery leads to better combustion, improving fuel efficiency. | More components mean higher production and repair costs. |

| The precision of multi-point injection helps ensure cleaner combustion, which means lower emissions. | Requires a sophisticated ECU to manage the precise timing of each injector. |

Direct Injection

Direct injection is the cutting-edge standard for both petrol and diesel engines, delivering maximum precision and efficiency. Unlike older systems that spray fuel into the intake port, direct injection delivers fuel straight into the combustion chamber.

How It Works:

- Fuel injectors operate under extremely high pressure, often exceeding 2,000 psi.

- Fuel is sprayed directly into the combustion chamber rather than the intake port.

- Inside the combustion chamber, the fuel mixes with air that’s already been compressed by the piston.

- This high-pressure spray atomizes the fuel into a fine mist, creating an optimal air-fuel mixture for combustion.

| Advantages | Disadvantages |

|---|---|

| Superior fuel atomization and mixing, leading to higher power output and fuel efficiency. | More expensive to design, manufacture, and maintain due to the complexity and high pressures involved. |

| More precise control over the air-fuel mixture, resulting in lower emissions. | Can lead to carbon buildup on intake valves, as fuel does not pass through and clean them as in port injection systems. |

| Enhanced performance, especially under high load and acceleration. |

Dual Injection Systems

Dual injection systems are the best of both worlds. By combining port and direct injection, these systems switch between or use both injection methods at the same time, depending on driving conditions. This versatility ensures optimal performance across various engine loads and driving styles, offering a balance of cleaner intake valves and maximum efficiency.

How It Works:

- Port injectors handle lower-speed or light-load conditions, keeping intake valves clean while maintaining fuel efficiency.

- Direct injectors kick in during high-load or high-speed conditions, delivering precision fuel spray directly into the combustion chamber for increased power and responsiveness.

- The system automatically switches or uses both injectors simultaneously, depending on what the engine needs at that moment.

| Advantages | Disadvantages |

|---|---|

| Combines the benefits of port injection (cleaner intake valves) and direct injection (better performance and efficiency). | Even more complex and expensive than single-system setups due to the combination of two technologies. |

| Improved flexibility in managing various driving conditions and optimizing performance. | Requires more advanced engine management and precision ECU calibration, leading to higher costs for design, production, and maintenance. |

Benefits of Fuel Injection Systems

Fuel injectors have revolutionized the automotive world, bringing major advantages over old-school carburetors. Let’s explore why fuel injection is now the go-to choice for modern engines and how it can boost both performance and efficiency.

Improved Fuel Efficiency

Fuel injectors are all about precision. By delivering the exact amount of fuel your engine needs, they reduce waste and maximize combustion efficiency. Whether you’re hitting the open road or stuck in city traffic, a well-tuned fuel injection system ensures every drop of fuel counts, leading to noticeable fuel savings.

Enhanced Engine Performance

Fuel injection systems adjust on the fly, responding to your driving conditions in real time. By monitoring things like throttle position and air intake, the ECU tweaks fuel delivery to match the engine’s needs. The result? Smoother acceleration, more responsive throttle, and better overall performance. Whether you’re cruising or pushing your car hard, modern fuel injectors ensure your engine keeps up.

Reduced Emissions

Fuel injectors played a huge role in reducing vehicle emissions, a big reason they’ve replaced carburetors. By controlling the air-fuel mixture more precisely, injectors lead to more complete combustion. This means fewer unburned hydrocarbons, less carbon monoxide, and reduced nitrogen oxide emissions, helping your car run cleaner and meet today’s strict emissions standards.

Better Cold-Start Performance

Cold weather starting was a nightmare with carburetors, but fuel injectors handle it with ease. Thanks to the ECU’s ability to adjust fuel delivery based on engine temperature, fuel injectors ensure smooth starts even in freezing conditions. This is especially handy in areas with harsh winters where reliable starts are a must.

Increased Reliability and Longevity

Fuel injection systems are built to last. With fewer mechanical parts than carburetors, injectors need less maintenance and provide consistent performance over time. Many modern injectors are even self-cleaning, meaning fewer clogs and fewer headaches down the road.

Adaptability to Modern Engines

Today’s engines demand precision, and fuel injection systems are up to the task. Whether it’s handling the high pressure of turbocharged engines or working with variable valve timing, fuel injectors adapt to the needs of modern engine tech. That makes them perfect for everything from compact cars to high-performance machines.

Diagnostic Capabilities

Modern fuel injection systems come with advanced diagnostic tools, making it easier to identify and fix issues. The ECU can detect problems with injectors, sensors, and other components, often flagging them with diagnostic trouble codes (DTCs) that you can read with an OBD-II scanner. This cuts down on guesswork and repair time.

Flexibility in Fuel Types

Fuel injectors aren’t limited to just gasoline or diesel anymore. Modern systems can handle ethanol blends and even some alternative fuels, giving automakers more flexibility to design engines for different fuel options. Whether it’s a standard gasoline engine or something more cutting-edge, injectors are built to handle it.

Common Issues with Fuel Injectors

Fuel injectors are key to keeping your engine running smoothly, but like any part, they’re not invincible. Over time, they can run into problems that impact performance and fuel efficiency. Recognizing the symptoms early can help you catch these issues before they turn into bigger headaches.

Clogging and Deposits

Fuel injectors work under high pressure, spraying fuel through tiny nozzles. Over time, those nozzles can get clogged with deposits from dirty fuel or additives. This restricts the fuel flow, causing a lean air-fuel mix that leads to rough idling, misfires, and power loss.

I once had a customer come in with their car barely idling. After running through the usual checks, it turned out their injectors were completely clogged from years of using cheap fuel. A quick professional cleaning brought their engine back to life. It’s amazing how something as simple as keeping injectors clean can make such a huge difference.

Symptoms:

- Rough idle

- Engine misfires

- Lower fuel economy

- Hesitation or stalling

Prevention and Fixes:

- Use high-quality fuel to reduce impurities.

- Add fuel injector cleaner to the tank regularly.

- For severe clogs, get the injectors professionally cleaned.

Leaking Injectors

Injectors are designed to open and close precisely, but they can start leaking over time. Internal leaks can flood the combustion chamber with too much fuel, while external leaks leave fuel pooling around the injector.

Symptoms:

- Fuel smell around the vehicle

- Difficulty starting

- Higher fuel consumption

- Poor engine performance

Prevention and Fixes:

- Inspect injectors and fuel lines regularly for leaks.

- Replace leaking injectors promptly.

- Ensure correct installation and proper seals when replacing injectors.

Electrical Problems

Fuel injectors rely on electrical signals from the ECU to work. Wiring issues, faulty connectors, or problems with the injectors themselves can interrupt those signals, causing fuel delivery problems and engine performance issues.

Symptoms:

- Misfires

- Rough running

- Check engine light comes on

- Inconsistent performance

Prevention and Fixes:

- Check injector wiring and connectors regularly.

- Use a multimeter to test for voltage and resistance.

- Replace any faulty wiring or connectors.

Wear and Tear

Like any mechanical component, fuel injectors are subject to wear and tear over time. The internal components, such as the valve and spring, can degrade, affecting the injector's ability to open and close properly. This wear can lead to poor fuel atomization and inconsistent fuel delivery.

Symptoms:

- Decreased engine performance

- Increased fuel consumption

- Unusual engine noises

- Rough idling

Prevention and Fixes:

- Follow the manufacturer's recommended maintenance schedule.

- Use high-quality fuel and regularly change the fuel filter to reduce contaminants.

- Replace injectors that show significant wear or damage.

Faulty ECU or Sensors

Fuel injectors depend on the ECU and sensors for correct timing and fuel delivery. A bad sensor or ECU problem can throw off the entire system, resulting in incorrect fuel mixtures.

Symptoms:

- Erratic performance

- Poor fuel efficiency

- Hard starts

- Check engine light comes on

Prevention and Fixes:

- Regularly test sensors and the ECU.

- Use a diagnostic tool to check for error codes.

- Replace faulty sensors or repair the ECU if necessary.

Fuel Quality Issues

Bad fuel can wreak havoc on injectors. Low-quality or contaminated fuel can cause deposits, clogs, and even corrosion, leading to injector failure.

Symptoms:

- Performance drop

- Higher emissions

- Clogged injectors

- Rough running

Prevention and Fixes:

- Always use high-quality fuel from reputable brands.

- Add a fuel system cleaner regularly to keep injectors clean.

- Replace the fuel filter on schedule to prevent clogs.

Frequently Asked Questions (FAQ)

What’s the difference between carburetors and fuel injection systems?

The main difference comes down to how they mix fuel and air. Carburetors use engine vacuum to pull fuel into the air stream before it enters the combustion chamber. Fuel injection systems, on the other hand, use high-pressure injectors to spray fuel directly into the intake manifold or combustion chamber. Fuel injection is way more precise, which means better fuel efficiency, improved performance, and lower emissions.

What’s the difference between MFI and EFI?

MFI (Mechanical Fuel Injection) and EFI (Electronic Fuel Injection) differ in how they control fuel delivery. MFI relies on mechanical parts like pumps and linkages to meter fuel based on engine demand, but it’s less precise and harder to adjust. EFI uses electronic control units (ECUs) and sensors to manage fuel injection. It’s much more accurate, efficient, and can adapt to changing driving conditions—making it the go-to system in most modern vehicles.

How do I know if my fuel injectors are failing?

If your fuel injectors are going bad, you’ll probably notice symptoms like rough idling, misfires, lower fuel economy, and a drop in power. You might also have trouble starting the engine or even smell fuel around the vehicle. If you’re seeing any of these signs, it’s a good idea to get your injectors checked out by a professional to avoid more serious issues.

Can fuel injectors be cleaned, or do they need to be replaced?

In many cases, fuel injectors can be cleaned to remove deposits and restore performance. Using fuel injector cleaner from time to time can help maintain them. If they’re heavily clogged or damaged, though, you might need a professional cleaning or, in some cases, a full replacement to keep your engine running smoothly.

How often should I service my fuel injectors?

Service intervals for injectors vary, but a good rule of thumb is to have them inspected and cleaned every 30,000 to 50,000 miles, depending on your driving habits and the fuel quality you use. Check your vehicle’s maintenance schedule for specific recommendations, and stick to the manufacturer’s advice to keep your injectors in good shape.

Are fuel injectors the same for petrol and diesel engines?

Nope, they’re different. Diesel injectors run at much higher pressures and are designed for diesel’s thicker fuel and unique combustion properties. Petrol injectors, on the other hand, work at lower pressures and are optimized for gasoline. Diesel engines usually use direct injection, while petrol engines can use both direct and indirect systems.

The Future of Fuel Injectors

As the automotive world shifts toward electric vehicles, the days of traditional fuel injection systems may be numbered—but they’re not going away just yet. Fuel injection will still play a vital role in hybrid vehicles and alternative fuel systems, where efficient fuel management is key to cutting emissions and improving performance.

While the internal combustion engine (ICE) market will shrink, the need for fuel injection innovations remains. These advancements will help support a smoother transition toward more sustainable solutions.

In short, even as the electric era takes over, fuel injectors will still have a place in the automotive world—especially in hybrid and alternative fuel vehicles. Their evolution will focus on boosting efficiency, lowering emissions, and adapting to new types of fuel, ensuring they stay relevant for years to come.