As the simplest and most efficient way of increasing horsepower, turbochargers were long reserved for performance cars. Today, though, turbochargers are an essential part of most modern engines due to the downsizing trend.

Turbochargers first appeared on compact European cars, adding extra power to light and nimble body shells. We can give props to the BMW 2002 Turbo and SAAB 90 Turbo, which started the turbo craze. Soon after, the whole automotive industry began using this simple yet magical device.

When it comes to non-performance vehicles, turbochargers first found their way into diesels, where they could make up for a lack of power. Meanwhile, in recent years, petrol engines have gotten smaller. Even performance cars switched from bulky naturally-aspirated engines to cleverly engineered turbocharged ones. Then, the trend reflected in the rest of the market segments. Thus, when it comes to internal combustion engines and until electric vehicles finally take over, turbos are here to stay.

While engines are getting smaller and turbos are getting bigger, or if you plan to repair or improve turbocharger systems, you'll need to know a thing or two about the different types available. To help you with that, here's everything you need to know about the different types of turbochargers, various advantages and drawbacks, as well as tons of valuable tips and tricks.

Enjoy!

Turbochargers 101

Turbocharging an engine is a forced air induction technique, but what does that exactly mean?

On naturally aspirated engines, the air comes in via natural airflow, filling the combustion chambers via atmospheric pressure. On the other hand, both turbochargers and superchargers compress air, literally boosting the volume of air sent into cylinders.

However, unlike superchargers, which are physically connected to the engine using a belt, drawing compressed air proportionally to the engine's RPM, turbochargers are driven by exhaust gasses. In turbocharged engines, the exhaust gasses can sometimes spin the centripetal turbine up to 150,000 RPM.

To do its thing, a turbo includes an exhaust turbine connected to an intake turbine via a small shaft. As the exhaust turbine spins, following the airflow in the exhaust system, it makes the intake turbine spin, sucking up air that is then compressed and sent into the combustion chambers.

More air into the cylinders also causes the ECU to inject more fuel to maintain the air/fuel ratio, resulting in bigger explosions and, ultimately, greater power. That is why forced induction engines are generally more potent than naturally-aspirated ones of the same displacement.

Different Types of Turbo Setups

Single turbo

A single turbo is the oldest and the most straightforward setup found on both petrol and diesel cars. The advantages of this setup are that it is easy to maintain and provides an adequate boost. However, its biggest flaw is the turbo lag.

Turbo lag is a term used to explain a gap in power delivery while the turbocharger builds up a boost. Turbocharged cars have this issue in particular, often resulting in unpredictable power delivery. Furthermore, bigger turbos have more lag as it takes more power to make them spin. Since single turbos are the least efficient ones, they need to be larger to produce as much energy as other types, resulting in manufacturers using bigger turbos, which explains why single-type turbos often have a more significant lag.

Parallel turbos

Sometimes, there's a need for two turbos to work simultaneously. This setup is called a parallel biturbo or parallel twin-turbo setup. In this case, two turbochargers operate in sync. In practice, this configuration is often found in V engines, where each turbo gives a boost to one cylinder bank.

Parallel turbo setups also allow us to use smaller snails for the same amount of boost while reducing lag.

Sequential turbos

Most performance cars today use a sequential twin-turbo setup to reduce the effects of turbo lag even more. This arrangement is much harder to construct than a single-turbo or parallel twin-turbo arrangement, requiring more thoughtful engineering, but it's also much more efficient.

A sequential turbocharger setup consists of one smaller turbo, operating at a lower RPM, and a bigger one, taking care of higher RPMs.

In this setup, the smaller turbo needs fewer exhaust gases to build up a boost. Meanwhile, bigger turbos operate more efficiently when the engine produces more exhaust gases at high RPM—combining both allows you to have the best of both worlds.

Twin-scroll turbo

First, twin-scroll turbo setups should not be confused with the twin-turbo type. Twin-scroll turbochargers have two separate inlets and two nozzles, resulting in decreased low-speed turbo lag, improved turbine efficiency, and reduced exhaust gas temperature and emissions. For example, BMW utilizes twin-scroll technology in its latest generations of turbocharged engines.

VGT (Variable Geometry Turbochargers)

Turbochargers with variable geometry were initially used on diesel engines. However, as technology progressed, their application in gas-powered passenger cars became more common. As a vehicle picks up speed, Variable Geometry Turbo alters the turbine housing via rotating vanes. Thus, this turbo achieves minimal lag and optimal performance from low to high speed.

Electric turbochargers

Recently, the internet got full of ads for cheap electric turbochargers, allegedly increasing power in a much simpler way than OEM turbochargers. However, these low-cost, low-quality units are nothing but a scam. They usually draw electricity without providing any boost in performance.

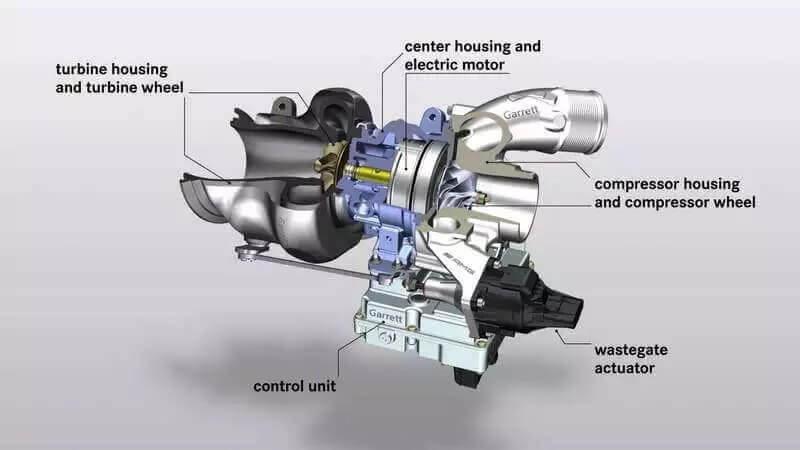

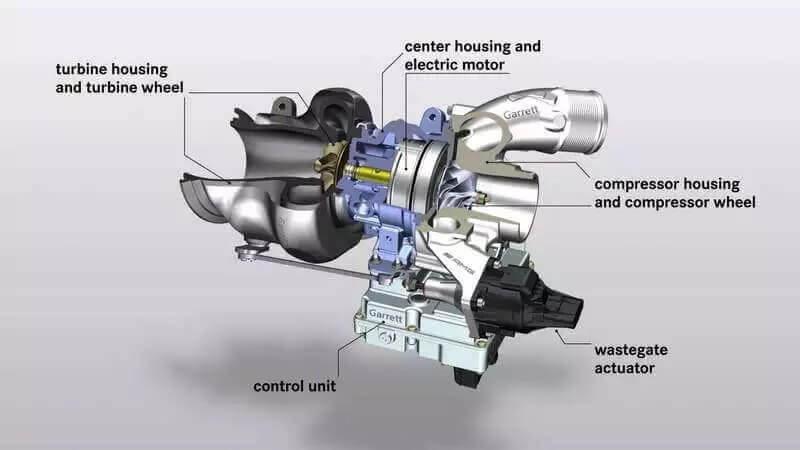

There are, however, electric turbochargers using an electric motor to overcome turbo lag at lower RPM. Audi, for instance, uses a 48V electric turbo on some of its vehicles, which cuts throttle response by 250 milliseconds. Moreover, Garrett is also working on developing e-Turbos for Mercedes-AMG and announced aftermarket electric turbochargers for 2021.

Journal bearing vs. ball bearings

The center hub rotating assembly is an essential part of the turbine since it allows it to spin at extremely high rotations with minimal friction. To keep friction to a minimum, manufacturers use two main types of bearings: ball bearings and journal bearings.

A ball bearing turbocharger is more durable and has a quicker spool. Meanwhile, a journal-bearing model is a more budget-friendly option. If you are building an aftermarket setup, you should research this topic more closely and opt for a solution that fits your budget.

Different Types of Turbo Cooling Systems

Air-cooled

Cooling is crucial since it helps the turbocharger last longer and prevents it from seizing under tremendous heat. Furthermore, a cooler turbocharger is also better performance-wise since it lowers the intake temperature. The lower the temperature, the denser the air entering the combustion chamber. And more oxygen means more power — simple as that.

As such, the intercooler's job is to lower the temperature of the air entering the turbo. However, it's counter-productive to invest big bucks on a quality intercooler if the cooler air is heated up when going through the turbo.

Liquid-cooled

Apart from air, manufacturers also use liquid to cool down turbochargers. In most cases, that liquid is motor oil that both lubricates and cools down the rotating parts of the turbine. Nonetheless, some turbochargers utilize a water and coolant mixture instead. Still, the basic working principle is pretty much the same: the coolants flow around the various components, bringing the temperature down.

Turbos by types of materials

Since turbochargers work on hot exhaust fumes, manufacturers utilize alloys that withstand thousands of miles of near-constant high-heat exposure. In addition to steel alloys, materials such as aluminum, titanium, magnesium, ceramic, and even carbon fiber are used in various turbine components.

Frequently Asked Questions (FAQ)

What is turbo lag, and how can it be minimized?

Turbo lag is the delay in power delivery when a turbocharger is building up boost. It can be minimized using setups like sequential turbos, twin-scroll turbos, and electric turbochargers that enhance low-end performance.

What's the difference between a single turbo and a twin-turbo setup?

A single turbo setup uses one turbocharger, offering simplicity and ease of maintenance but often with more turbo lag. A twin-turbo setup can either use two turbos working simultaneously (parallel) or sequentially, reducing lag and improving power delivery.

How does a twin-scroll turbo differ from a twin-turbo system?

A twin-scroll turbo uses two separate inlets and nozzles within a single turbocharger to enhance efficiency and reduce lag. In contrast, a twin-turbo system uses two separate turbochargers to manage different RPM ranges or to boost separate cylinder banks.

Are electric turbochargers effective?

High-quality electric turbochargers, like those used by Audi, can be effective in reducing throttle response time and enhancing performance. However, low-cost aftermarket electric turbos are often scams and do not provide any real performance benefits.

What cooling methods are used for turbochargers, and why are they important?

Turbochargers use air-cooled and liquid-cooled methods to manage heat. Cooling is crucial to prevent the turbocharger from seizing under high temperatures and to enhance performance by ensuring cooler, denser air enters the combustion chamber.

Last Words

Turbochargers have come a long way since their early days and are now an essential part of most engines, whether in city commuters, big performance cars, or ambitious aftermarket builds. This evolution has made turbos more efficient, reliable, and versatile, cementing their place in the automotive industry.

If you own a factory-equipped turbocharged car as a daily driver, always make sure to get your hands on your car's repair manual to follow the right maintenance schedule. Turbocharger issues could lead to bigger breakdowns and costlier repairs, so always ensure your car's turbo is in optimal working order. We'll never repeat it enough: preventive maintenance is still your best bet to keep expensive repairs away.

For those building a custom turbo setup in the quest for speed, don't fall for marketing gimmicks and ensure you source your parts from reputable manufacturers. Remember that turbos and engines have their limits, so choose your setup wisely to achieve the best balance of performance and reliability.

Whether you're boosting a daily driver or building a high-performance machine, understanding and maintaining your turbo system is key to enjoying all the benefits these incredible devices offer.