To meet higher lower emission requirements while also increasing power, vehicle manufacturers use a complex ECU in their engines. The Engine Control Unit decides when to inject fuel, when to fire the sparks, manipulate the valves, etc. And it does all of that by getting information from the crankshaft and camshaft position sensors. Once you realize how crucial these sensors are to the good working operation of your engine, it's not hard to understand that, when they fail, they can cause all sorts of faults. To help you quickly find out what's wrong the next time your car has a CKP sensor problem, we've created this exhaustive guide explaining what a crankshaft sensor does, as well as covering the most common faulty CKP sensor symptoms and what you can do to fix it.

Back To Basics

The crankshaft sensor monitors the position and rotation speed of the crankshaft. In modern engines with an electronically-controlled fuel injection system, the crankshaft sensor tells the ECU when it’s time to inject fuel and power up the spark plugs. That way, the engine can give you more power when you need it but also be super-efficient when you drive carefully.

Now, that was quite the oversimplification, but the crankshaft sensor and the ECU improved the overall efficiency of the engine. And, crucially, modern internal combustion engines won’t work at all when the crankshaft sensor is disabled. With a bad crankshaft sensor, the ECU won’t be able to tell when to inject fuel or fire the plug.

Consequently, if your car just stalled and you can’t start it, one of the culprits might be a bad sensor. To be sure, though, you might want to check out the symptoms list below carefully.

Also, driving a car with a crankshaft sensor sending incorrect readings for an extended period can lead to severe damage inside the engine. under these conditions, driving your car or trying to start the engine might not be the best practice.

Of course, I’m not trying to scare you, but being cautious is always the best practice when it comes to engines.

How Does A Crankshaft Sensor Work?

Depending on the car, the crankshaft sensor uses either a pick-up coil or the Hall effect. The former type was mostly used on older vehicles and used a pick-up coil to detect a magnetic field. The latter uses the Hall effect, which is the principle of measuring the voltage difference across a conductor.

You can easily differentiate between these sensors, even without having to take them apart. A pick-up coil magnetic sensor usually has a two-pin connector, while the Hall-effect sensor has a three-pin connector. Some exceptions apply but it's not that common.

The crankshaft sensor gets its reading from the teeth of the reluctor ring, which is directly connected to the crankshaft. Engineers leave a few teeth from the ring missing, which will create a pattern as the crankshaft turns. The ECU then uses these notches in the pattern as reference points.

Crankshaft position sensors can be installed in various positions. Depending on the engine, you can find the CKP sensor on the cylinder block, crankshaft pulley, or transmission bell housing.

If you aren’t sure where the sensor is in your vehicle, you can always take a quick look in the "component location" section of your vehicle's repair manual.

Symptoms of a Bad Crankshaft Sensor

Many symptoms may arise due to a bad crankshaft sensor. All of these issues are directly connected to the proper operation of the engine, and they’re easily discernible. There is no need to mention that when your car stalls on you, you should be able to notice it quite fine. That being said, different symptoms may occur depending on if the sensor works intermittently, if it sends incorrect readings or if it doesn't work at all.

The Check Engine Light is On/Flashes

As soon as the crankshaft sensor fails, no matter if it's permanent or intermittent, the check engine light will illuminate. Unfortunately, the check engine light can come up as a result of a myriad of other engine issues. This usually leaves drivers clueless about what the problem is and how to fix it.

One way to check if the crankshaft sensor is defective is with an OBD2 tool. These tools are very inexpensive nowadays, specifically those that show only the error code. This type of scan tool won't give you a description of the problem, but you can just Google it, and you'll find it right away.

For example, a P0335 (Crankshaft Position Sensor A Circuit Malfunction) error code means that there's a problem in the CKP sensor's electrical circuit. A wire may be cut or skinned, creating a short-to-ground condition, the coil inside the sensor might be open or short, etc. In all cases, it will have something to do with the electrical circuit.

Many other codes are related to a faulty CKP sensor, but we won't cover them all here. If you'd like to know more about it, check this article here.

Still, bad crankshaft sensor symptoms usually go beyond an illuminated check engine light. In most cases, you’ll probably be able to feel the engine misbehaving in many ways too. We'll discuss that in more detail below.

The Engine Won’t Start

The first thing you may notice when a sensor is bad is trouble starting the engine. When the CKP sensor sends incorrect readings, the ECU will inject fuel and fire spark plugs erratically. As a result, the engine might flood, or it might not start at all.

Also, if the engine needs a longer cranking time or simply won't start, then the crankshaft sensor might be failing.

In all cases, don’t be too persistent. Keep cranking the engine, and the battery will deplete. You may even flood the plugs, which will make the engine even harder to start.

Intermittent Stalling

While this doesn’t often happen while driving, a bad crankshaft sensor can stall the engine, especially when it's just about to fail for good. Intermittent stalling occurs most of the time due to CKP problems, which are frequently caused by damaged wiring or connectors.

Uneven or Unresponsive Acceleration

A CKP sensor sending incorrect data to the PCM tends to cause uneven acceleration. Depending on the fault, the engine may lack power for brief periods while accelerating. The engine might stutter, jerk, and even stall.

This usually happens because the engine doesn't send the fuel or doesn't time the sparks correctly, leading to an incorrect air/fuel ratio. Such a condition will often create misfires which will be most noticeable under hard accelerations.

Cylinder Misfiring and Vibrations Coming from the Engine

One of the most common symptoms of a bad crankshaft position sensor is misfires. You can easily notice a cylinder misfiring if you hear pops and bangs coming from the engine. Misfiring cylinders will cause the vehicle to stutter, backfire, and a strong smell of gasoline in the cabin.

How to Start a Car with a Bad Crankshaft Sensor

Once a crankshaft sensor completely dies out, the engine will probably not start. In that case, replacing the sensor is the next obvious step. On some other cars, however, the CKP sensor is only used to monitor the engine for misfires and the PCM relies on the camshaft sensor to time the injection and sparks instead. In that case, you might still be able to start the engine. The real question is – should you do it?

Well, if you just started experiencing issues, then it’s probably safe to start the engine, albeit with some difficulties. If you succeed, you should be heading to the nearest auto repair shop right away, though.

If you're having problems with your car's CKP sensor and you are looking for a way to move it, check out this in-depth guide about how to start a car with a bad crankshaft sensor.

How to Replace a Crankshaft Sensor

On most vehicles, replacing a crankshaft position sensor is quite simple actually. However, you should know what you’re doing and have some basic knowledge of engine mechanics.

If you’re really into it, be sure that you have the correct tools for the job. To lift your car, you will need a floor jack and jack stands for increased safety. To remove the sensor from the engine, you’ll need a ratchet and socket set. On some vehicles, you might also need an OBD2 tool to erase the error codes. As far as tools go, that's pretty much it.

Also, be sure to be aware of where the CKP sensor is before you get under the car. Googling it or using a repair manual might help. Then, follow these steps:

- Jack up your vehicle on the side where the sensor lies. For maximum safety, put jack stands under it.

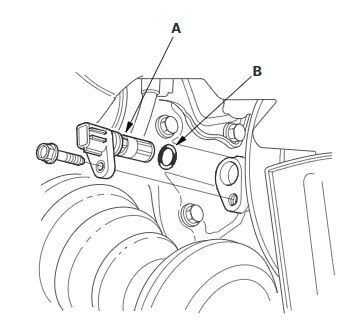

- Locate the sensor and unplug the connector.

- Unscrew the bolt holding the sensor in place. Then, lightly twist the crankshaft sensor assembly and remove it from the housing. Be sure to remove the old O-ring as well. If the crankshaft sensor casing is cracked, do not break it in half. CKP sensors sometimes stick into the engine block and might break flat with the block.

- Lubricate the new o-ring with white grease and install it on the new sensor. Insert the new sensor in its place and carefully push it while lightly twisting it. Next, screw in the bolt that holds the sensor in place and tighten it according to specs.

- Reconnect the electrical connector to the sensor assembly.

- Raise your car a little – remove the jack stands first, and then lower the floor jack.

- Finally, use an OBD2 tool to erase any error codes that could have been recorded because of the fault.

Frequently Asked Questions (FAQ)

What is a crankshaft sensor, and why is it important?

A crankshaft sensor monitors the position and rotation speed of the crankshaft in an engine. It sends crucial information to the Engine Control Unit (ECU) to regulate fuel injection and spark timing, ensuring optimal engine performance. Without a functioning crankshaft sensor, the engine may not start or run efficiently.

What are the common symptoms of a failing crankshaft sensor?

Symptoms include difficulty starting the engine, intermittent stalling, uneven acceleration, cylinder misfires, and the check engine light turning on. These issues can significantly impact engine performance and should be addressed promptly.

Can I drive my car with a faulty crankshaft sensor?

While it's possible to drive with a failing sensor, it's not advisable. A malfunctioning crankshaft sensor can cause the engine to misfire or stall unexpectedly, which can be dangerous. It’s best to replace the sensor as soon as possible to avoid further damage.

How can I diagnose a bad crankshaft sensor?

You can use an OBDII scan tool to check for error codes like P0335, which indicates a malfunction in the crankshaft sensor circuit. The tool will provide a code that you can look up to confirm the issue. If you're unsure, consult a professional mechanic for a thorough diagnosis.

Is replacing a crankshaft sensor a DIY job?

Replacing a crankshaft sensor can be a straightforward task if you have basic mechanical knowledge and the right tools. However, it involves lifting the vehicle and accessing the engine components, so if you're not confident, it's best to have a professional handle it.

Last Words

It's common to hear people brush off issues like a "bad sensor" as minor nuisances. However, in modern vehicles, sensors are crucial to the engine's overall function and efficiency. The crankshaft sensor, in particular, is a key player in ensuring your engine runs smoothly. Ignoring a faulty sensor can lead to significant problems, from misfires to complete engine stalls, leaving you stranded or worse.

So, the next time that check engine light flickers on or you notice symptoms like intermittent stalling or rough acceleration, don't just shrug it off. Take your car to a trustworthy auto mechanic who can diagnose the problem accurately. They can ensure your vehicle's sensors function correctly, keeping your engine in top shape.

For those who enjoy getting their hands dirty, tackling the repair yourself is an option. Make sure to grab your car's repair manual before diving in. This will provide you with the manufacturer's recommended replacement procedure, ensuring you do the job right the first time. Not only will you gain a deeper understanding of your vehicle, but you'll also save a bundle on labor costs.

Remember, in modern engines, sensors are vital components that keep everything running smoothly. Addressing a faulty sensor promptly can prevent more severe issues and keep your car running efficiently and safely.