In recent years, engineers went to great lengths to improve the overall efficiency of modern internal combustion engines. And the best way to do that is by precisely controlling the ignition and fuel injection timing. For that reason, every modern engine has a crankshaft and camshaft position sensor, which then sends much-needed data to the ECU. But what does a camshaft sensor do? And, above all, what happens if it stops sending information to the ECU? I’ll answer both questions in detail below – be sure to check the symptoms to see if you have a bad camshaft sensor. Also, if you feel like it, you can learn about how to replace the camshaft sensor yourself. Let’s dig in!

How Does a Camshaft Sensor Work?

I've already covered the crankshaft sensor and the symptoms you might have when it goes bad in a previous post. Now, I’ll also cover its accompanying part, the camshaft position sensor. As its name implies, this sensor measures the position of the camshaft, but also the angular velocity.

In Theory

The camshaft sensor is crucial for the proper functioning of modern motors. Without it, most engines won’t work correctly, and sometimes they won’t work at all. That’s especially true in engines with Variable Valve Timing (VVT), which alters the timing of the valve lift event.

Thanks to the camshaft sensor, the ECU always knows the exact moment when to inject the fuel and when to ignite it. Moreover, modern engines can also control the amount of air that enters the engine. Because of that, the engine always works optimally. When you need power, it can instantly deliver it. When not, it can switch to economy driving and save as much fuel as possible.

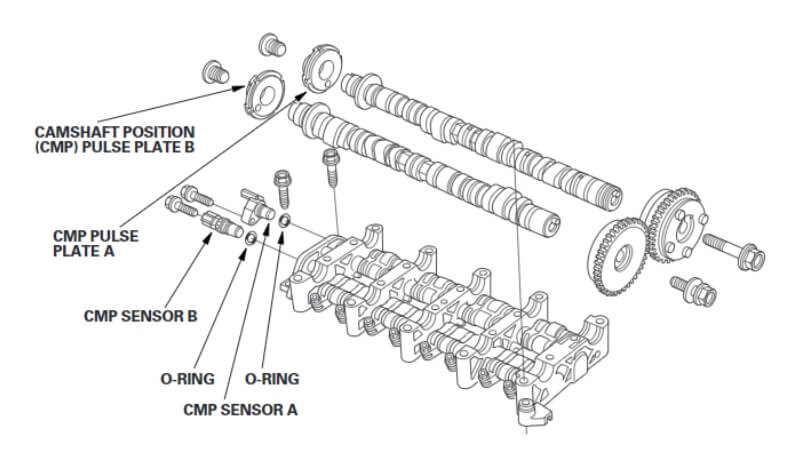

The camshaft sensor sits near the engine head, more precisely, near the timing rotor on the camshaft of the engine. The sensor detects the position by monitoring changes in the magnetic field. To identify these changes, the timing rotor usually has some teeth missing. As soon as the missing teeth encounter the sensor, there is a drop in the magnetic field.

The camshaft position sensor then sends that data to the ECU. Afterward, the computer processes the data and calculates the exact position and angular velocity of the camshaft. The ECU uses the data to assess when to inject fuel, ignite the mixture, or change the valve timing.

There are two different camshaft sensors utilized in modern vehicles – magnetic and Hall-effect models.

The magnetic sensor has a pickup coil and produces an AC sine-wave signal. It is usually connected by two wires and needs no external power source.

A Hall-effect sensor, on the other hand, uses the voltage difference across an electrical conductor. This sensor produces a digital square-wave signal that measures only on- or -off condition. The Hall-effect sensor only works with an external power source, which is why it connects via three wires instead.

For a complete picture of the position of the internal parts, the ECU also uses data from the crankshaft sensor. The camshaft and crankshaft sensor always work in unison.

[one_half]

[/one_half][one_half_last]

[/one_half_last]

In Practice

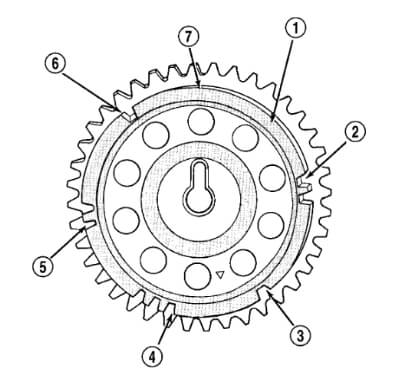

To give you a concrete example, let's take a 2005 Dodge Caravan. This vehicle uses a Hall-Effect sensor so it generates pulses as groups of notches on the camshaft sprocket pass underneath it. The PCM keeps track of the crankshaft rotation and identifies each cylinder by the pulses generated by the notches on the camshaft sprocket. Four crankshaft pulses follow each group of camshaft pulses.

When the PCM receives 2 cam pulses followed by the long flat spot on the camshaft sprocket, it knows that the crankshaft timing marks for cylinder 1 are next. If the PCM receives one camshaft pulse after the long flat spot on the sprocket, cylinder number 2 crankshaft timing marks are next, and so on.

When metal aligns with the sensor, the voltage goes low (less than 0.3 volts). When a notch aligns with the sensor, voltage switches high (5.0 volts). As a group of notches passes under the sensor, the voltage switches from low (metal) to high (notch) then back to low. The number of notches determines the number of pulses. Easy right?

It may sound easy at first but to know if the pulse pattern is right and if the CMP sensor works correctly, you'll need an oscilloscope. It's simply impossible to monitor the pattern using a multimeter as the camshaft turns way too fast to visually see the drop in voltage.

Most Common Bad Camshaft Sensor Symptoms

Many engine-related issues can arise if you have a faulty camshaft sensor. These signs don’t necessarily mean that the problem is within the sensor, however. Bad wiring can also cause the same manifestations, but also other engine parts can be the culprit. That's why it's always important to test the sensor before replacing it. More on that later.

The Check Engine Light is On

Each time the camshaft sensor doesn’t work correctly, the “Check Engine” light on your dashboard will illuminate. The problem is, this light can refer to many different issues. For that reason, you'll need an OBDII scan tool to read the code and know what's up.

Once you have the code, look into your car's repair manual to learn more about what it means and find the specific troubleshooting procedure based on the code recorded in the PCM.

Problems Starting the Car

The camshaft sensor is directly responsible for proper engine operation. Because of that, when it fails, the engine might have trouble starting, or it won’t start at all.

Rough Idling and Jerkiness While Driving

If the engine isn’t smooth while idling, or it’s jerky when driving, it might relate to a faulty sensor. You might also feel a sudden drop in power while driving.

Overall Performance Drop

Due to improper balance between fuel injection and firing, you might experience an overall performance drop. If your engine feels dull during acceleration, it might relate to a bad camshaft sensor.

Misfires

Same thing here. If the engine doesn't inject or ignite the fuel at the right time, some cylinders may misfire and the engine might jerk and stall under load.

Increased Fuel Consumption

In some cases, the ECU might inject more fuel than necessary into the engine, which can adversely affect the fuel economy.

The Engine Completely Stalls

In rare cases, the engine might completely stall while you’re driving. When this happens, be sure not to panic and immediately try to find a safe place to park the vehicle.

Can You Drive Your Car with a Bad Camshaft Sensor?

In most situations, the engine will continue to work if the camshaft sensor doesn’t send the correct data. As soon as a fault is detected, powertrain control modules are smart enough to be able to leave that data aside and rely on other sensors instead. In some cases, default mapping may also be used to keep the engine running as long as possible.

However, that doesn’t mean that you should plan a long trip. Instead, take your vehicle to an auto repair service for diagnostics asap. The sensor certainly won’t get better if you continue driving without alleviating the issue. And, while not as dangerous as having a bad crankshaft sensor, prolonged driving can have an impact on other engine parts.

The fact that it's still running doesn't mean it can't damage other expensive components. Furthermore, when an engine is running on default mapping alone, it will typically consume more fuel than required, also called a "rich" condition. When burning rich, not only will it cost you more in fuel but the excess fuel may sometimes accumulate in the catalytic converter which may, in turn, need to be replaced too.

Besides, if the sensor fails while you drive on the highway, it can completely stall the engine. That’s not only uncomfortable, but it also poses a safety risk for you and other traffic participants.

How Much Does It Cost to Replace a Camshaft Sensor?

The price of the sensor varies greatly. Original OEM parts usually cost much more, but even then, there is a variation in the amount. Overall, though, you will pay from $40 to $200 for a new sensor.

Luckily, CMP sensors are usually located on the side of the engine and are quite easy to access and remove. If you take your car to an auto repair service, they might charge you $50 to $100 for labor.

Common DTC Codes

While replacing a camshaft sensor isn’t too hard, you still need to diagnose the issue first. To do that, you’ll need an OBDII tool to find the error codes. Most common codes for failed camshaft sensor are:

- P0340 - Camshaft Position Sensor Circuit Malfunction signifies a circuit malfunction. The issue could be due to a failed sensor, but also other components, such as wires.

- P0341 - Camshaft Position Sensor Circuit Range/Performance signifies a circuit range or performance problem. This issue could be due to a faulty sensor, but also damaged or misaligned reluctor wheel or bad connection.

- P0342 - Camshaft Position Sensor Circuit Low Input signifies a low input in the circuit. The issue means that the signal is too weak and refers to connection issues.

- P0343 - Camshaft Position Sensor Circuit High Input signifies a high input in the circuit. The issue means that the signal is too strong. It usually happens when there is moisture or oil on the sensor.

- P0344 - Camshaft Position Sensor Circuit Intermittent signifies an intermittent circuit problem or a missing signal from the sensor.

Also, make sure to look out for any other DTC codes related to misfires (P0400-0408) and O2 sensors (P0030-P0064 and P0130-P0175). These codes could be collateral to the CMP sensor problem.

How to Diagnose and Replace a Faulty Camshaft Sensor?

Now, even when you find the error code, it won’t tell you exactly where the issue is. For that reason, I recommend checking the wiring first and then resorting to replacing the sensor. As mentioned earlier, testing a CMP sensor often requires the use of an oscilloscope to monitor if the pulse pattern is fine and if the problem actually comes from the sensor itself. Once you’re sure that the sensor is the culprit, here is what you need to do:

Locate the camshaft position sensor. It should be mounted on the engine head or front cover and connected with two- or -three wires. If you aren’t sure where it is or what it looks like, you can find its exact position in the "component location" section in your car's repair manual.

Instructions

Obviously, different cars will have different CMP sensors at different locations so the replacement procedure may differ. However, here's a generic procedure that can be applied to most of them.

- Disconnect the black (negative) cable from the battery before you start working;

- Unplug the sensor's connector;

- Unscrew the mounting bolt that holds the sensor to the engine using a wrench;

- Twist the sensor slightly while pulling carefully. It should come out right away. Make sure that you also remove the O-ring of the old sensor;

- Attach the new sensor with an inward motion and a slight twist. Make sure to put a bit of engine oil on the new O-ring so it slides right back in;

- Tighten the new sensor into place;

- Plug the connector back into the new sensor;

- Reconnect the battery;

- Erase the DTC codes using an OBDII scan tool;

- Start the engine and make sure the code doesn't come back.

Final Words

Camshaft sensor failure happens more often than you think, especially on older vehicles. If it happens to you, don’t panic – the issue is usually not that severe. Nonetheless, you should always react quickly whenever the check engine light comes up to protect other engine parts from potential damage.

Since testing a camshaft sensor often requires professional equipment, your best bet might be to bring your car to the nearest shop, have the sensor tested and then go back home and replace it yourself. When in doubt, always remember to get your hands on your vehicle's repair manual first and follow the recommended replacement procedure.

Good luck!